Name: Michael

Industry: Production and processing industry

Cooperation time: July 2022

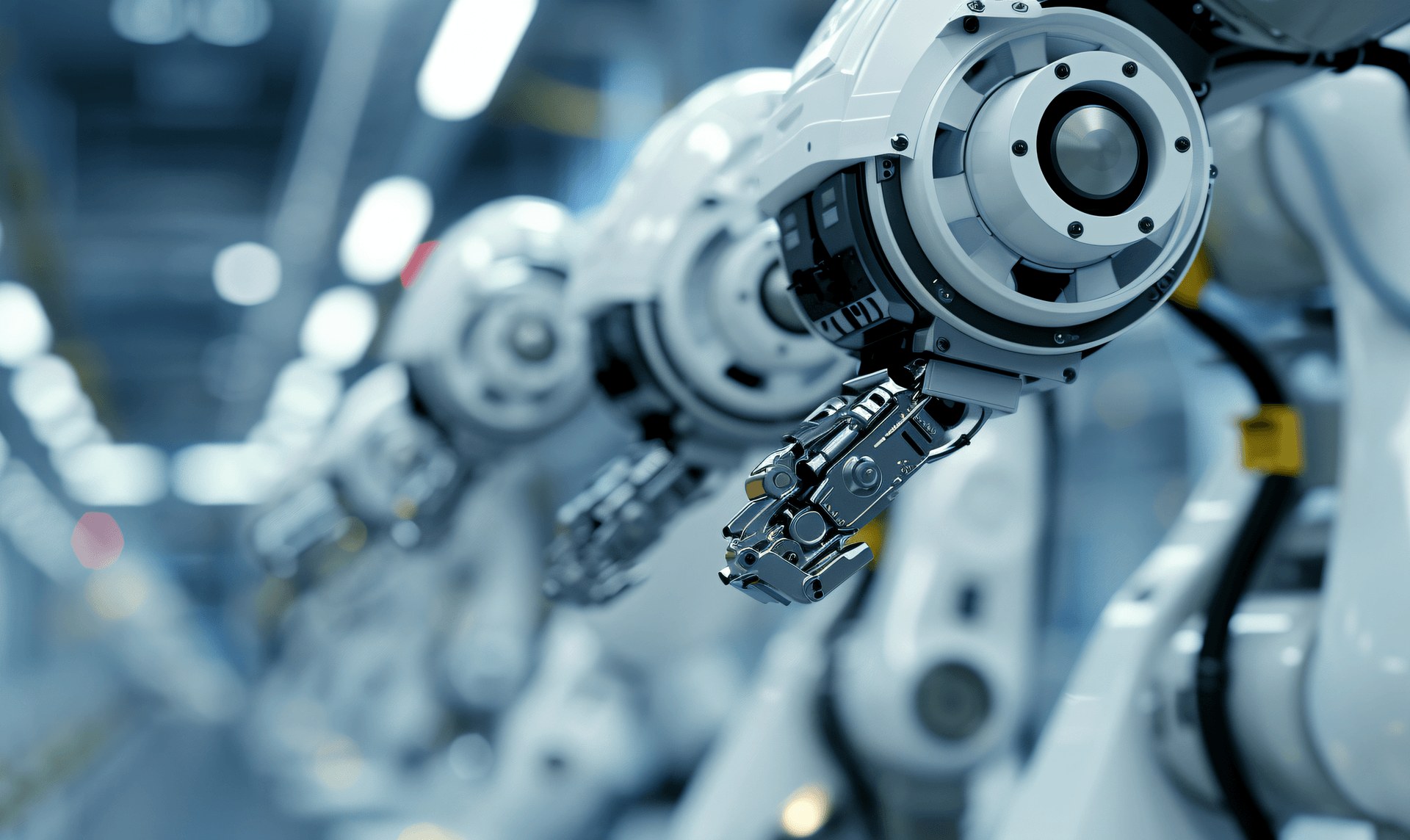

With the continuous advancement of industrial manufacturing technology, cutting equipment is developing towards high precision, high efficiency, low noise and intelligence. Especially in high-strength use scenarios such as metal processing, composite material cutting, and building formwork customization, higher requirements are put forward for the performance of the motor system.

Our customers are a European-based manufacturer of smart cutting equipment that specializes in custom cutting solutions for building materials, aluminum profiles and composite sheets. They are developing a new generation of smart cutting machines, with the goal of improving market competitiveness and meeting users' needs for stable operation, precise control and low maintenance costs.

1.Overheating under high-load operation: Existing cutting motors couldn’t handle extended cutting cycles without thermal failure.

2.Unstable torque: When cutting layered or high-resistance materials, the torque output would fluctuate, resulting in uneven cutting quality.

3.Strict spatial constraints: The internal motor chamber was limited in size and required non-standard shaft and mounting options.

4.Low-noise requirement: The laser cutter motor needed to meet a noise limit of ≤ 40dB during full-load operation.

5.Industrial protection level: The working environment was dusty and prone to oil splashes, requiring a durable, sealed motor structure.

To address all of the client's challenges, we delivered a customized high-performance brushless DC motor system, designed specifically for industrial cutting applications.

Model: BG-57BLDC-H Series

Voltage: 48V DC

Rated Power: 750W

Rated Speed: 3000RPM

Rated Torque: 2.4 N.m

Peak Torque: Up to 7 N.m

Efficiency: ≥ 85%

Cooling Mechanism: Aluminum alloy shell with high-efficiency heat dissipation fins + optional external fan cooling for continuous operation.

Noise Level: ≤ 40dB, achieved through optimized rotor balance, high-precision bearings, and noise-suppressing magnetic design.

Shaft: CNC-machined shaft per client’s drawing, including flat sections and threads for locking components.

Mounting: Customized flange and bolt hole positions for seamless machine installation.

Motor Diameter: 57mm; compact enough to fit the tight internal cavity of the machine.

Protection Grade: IP65.Dust-proof sealing.Oil-resistant gaskets.Conformal coating for PCB and connectors

Connector Type: Industrial-grade waterproof aviation connector

Encoder integration for precise speed/position control

Planetary gearbox (optional) for lower speed, high-torque applications

Brake (optional) for vertical mounting cutting tools requiring quick stop

Technical Documentation: Each delivery includes wiring diagrams, 3D CAD files, installation guides, and test curves.

Onboarding Support: One-on-one engineering support during initial motor integration phase.

Performance Reports: OEM laser machine motor factory test reports with current, torque, efficiency, and noise values for quality verification.

Warranty & Maintenance: 24-month product warranty, with optional extension plans.

Spare Parts Supply: Long-term availability of replacement parts and accessories.

Remote Monitoring Support: For smart controllers, we provide firmware updates and remote diagnostic assistance

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.