The user is a manufacturer and equipment integrator of mixers, and its products are mainly exported to the United States and European markets, and the application fields cover food processing,

building material mixing and general industrial mixing equipment.

The end customer has clear requirements for the starting performance, operation stability and product consistency of the equipment, and hopes to control the manufacturing cost of the whole machkineunder the premise of ensuring performance.

In this mixer project, the equipment needs to be directly connected to AC 110V / 220V mains power to work, and the viscosity of the material changes greatly during the mixing process, and there are

large load fluctuations in the start-up and operation stages. In addition, the whole machine has a compact structure, and there are strict restrictions on the outer diameter size, installation method and

output shaft structure of the motor.

Based on the above background, the user hopes to choose a motor with high starting torque, mature structure and high cost performance as the main drive unit of the mixer.

In the project development and selection stage, users mainly face the following problems:

Insufficient starting torque: Ordinary single-phase asynchronous motors perform unstable when starting at full or half load

Poor load adaptability: Material changes during mixing process lead to fluctuations in rotational speed

High requirements for temperature rise control: long-term continuous operation has a significant impact on the life of the motor

Low structural matching: It is difficult for standard motors to directly match the internal installation structure of the mixer

High requirements for export consistency: it is necessary to ensure stable mass production performance and reduce after-sales risks

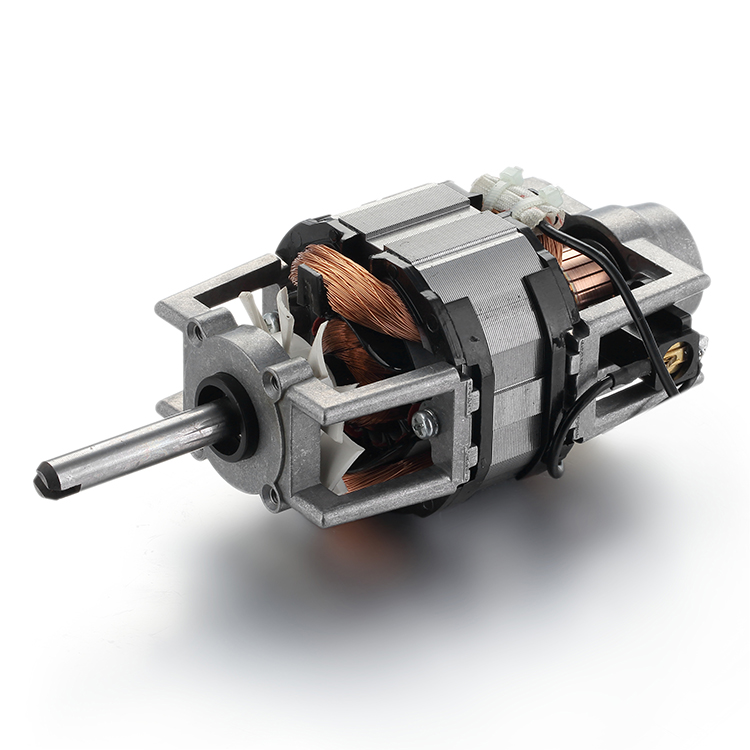

For the actual working conditions of the mixer, BG Motor provides users with customized solutions for the single-phase series excitation motor BGAC95.

The core content of the plan:

It adopts a single-phase series excitation (Universal Motor) structure and has a naturally high starting torque characteristic

According to the heavy load starting requirements of the mixer, the stator winding design is optimized to match the rotor parameters

Optimize the carbon brush and commutation system to reduce operating sparks and wear and improve reliability

Customize the output shaft length, shaft diameter and mounting hole position according to the user's whole machine structure

Overheating protectors and EMI suppression solutions can be integrated to improve the safety and compliance of the whole machine

This solution avoids complex control systems while ensuring performance, and the overall structure is mature and cost-controllable, making it suitable for large-scale applications.

Application effect:

In the whole machine test and batch application, the user has achieved the following results:

The mixer starts quickly and runs smoothly

Under different material conditions, the rotation speed is stable and the mixing efficiency is high

The temperature rise of the motor is well controlled, and the service life is significantly improved

The whole machine has high consistency and is suitable for long-term export sales

Achieve the ideal balance between performance and cost

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.