Modern medical technology is growing fast, demanding precise and reliable solutions to support better patient care and equipment performance.

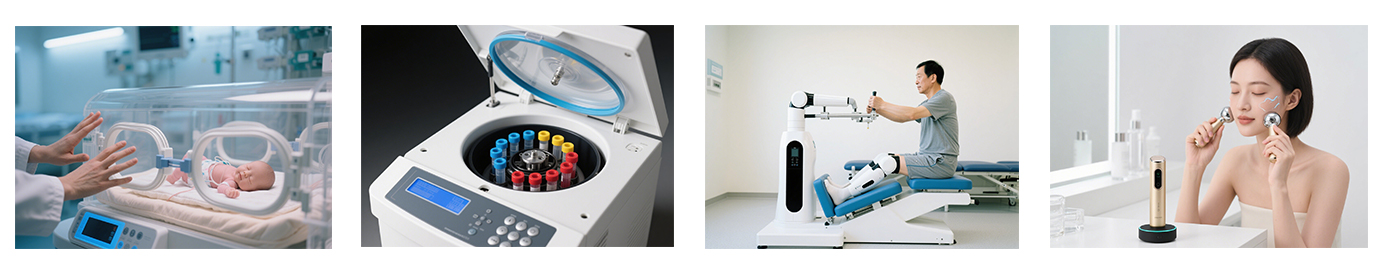

Medical-grade needs appear everywhere: from infant incubators to beauty checkups and elderly rehabilitation devices, motors must ensure safety, stability, and low noise in daily healthcare applications.

Healthcare innovation is accelerating—read on to discover how the right medical-grade motors empower high-performance medical devices.

Medical-grade products are designed to meet strict safety, precision, and durability standards required in healthcare environments. Examples include:

Medical centrifuges for sample analysis

Ventilators and respirators for patient care

Infusion pumps and dialysis machines for fluid control

Electric hospital beds and patient lifts with smooth, controlled motion

Diagnostic imaging equipment such as CT scanners and MRI-compatible devices

Portable rehabilitation and therapy machines

All these products rely heavily on medical motors, gearbox motors, or high-torque DC motors with gearboxes. They must operate quietly, maintain long service life, and meet the strict performance demands of OEM medical device companies.

The medical motor market is driven by three major categories: DC motors, AC motors, and gear motors.

DC Motors: Provide controllable speed, low noise, and stable torque. They are widely used in medical pumps, electric wheelchairs, and surgical robots.

AC Motors: Deliver high and stable power output. Ideal for hospital ventilation systems, sterilization machines, and high-speed centrifuges.

Gearbox Motors: Compact motors integrated with gear reduction for higher torque. High-torque DC motors with gearboxes are critical in rehabilitation equipment, operating tables, and patient lift systems.

Leading medical-grade motor manufacturers also provide customized motor assemblies with encoders, brakes, planetary gearboxes, and IP-rated protection to ensure reliable performance in sterile or sensitive environments.

To qualify as medical-grade motors, several essential requirements must be met:

Low Noise and Low Vibration – Critical for patient comfort in applications like infant incubators and sleep lab equipment.

Compact Size with High Torque – Many devices require small electric motors that can deliver powerful output in portable medical devices.

Long Service Life – Continuous and repetitive use in rehabilitation devices and diagnostic machines requires durable motors.

Safety and Reliability – Motors must comply with CE, RoHS, and FCC certifications for OEM medical device companies.

Energy Efficiency and Precision Control – Especially in brushless DC medical motors for robotic surgery tools and infusion systems.

These requirements ensure that medical-grade motors contribute to safer, quieter, and more efficient medical equipment.

BG Motor has become a trusted partner in supplying medical-grade motors for centrifuge applications, a critical component of laboratory and clinical testing.

High-Speed and Low-Vibration Performance – Our brushless DC motors deliver stable torque and reduce sample errors during rapid spinning.

Durability Under Continuous Operation – Designed for long service life even under frequent start-stop cycles.

Custom Gearbox Options – When higher torque is needed, we integrate gearbox motors to handle heavy sample loads.

Our motors are optimized for clinical laboratory centrifuges, blood separation devices, and biochemical testing equipment, helping OEM medical device companies enhance accuracy and reduce maintenance.

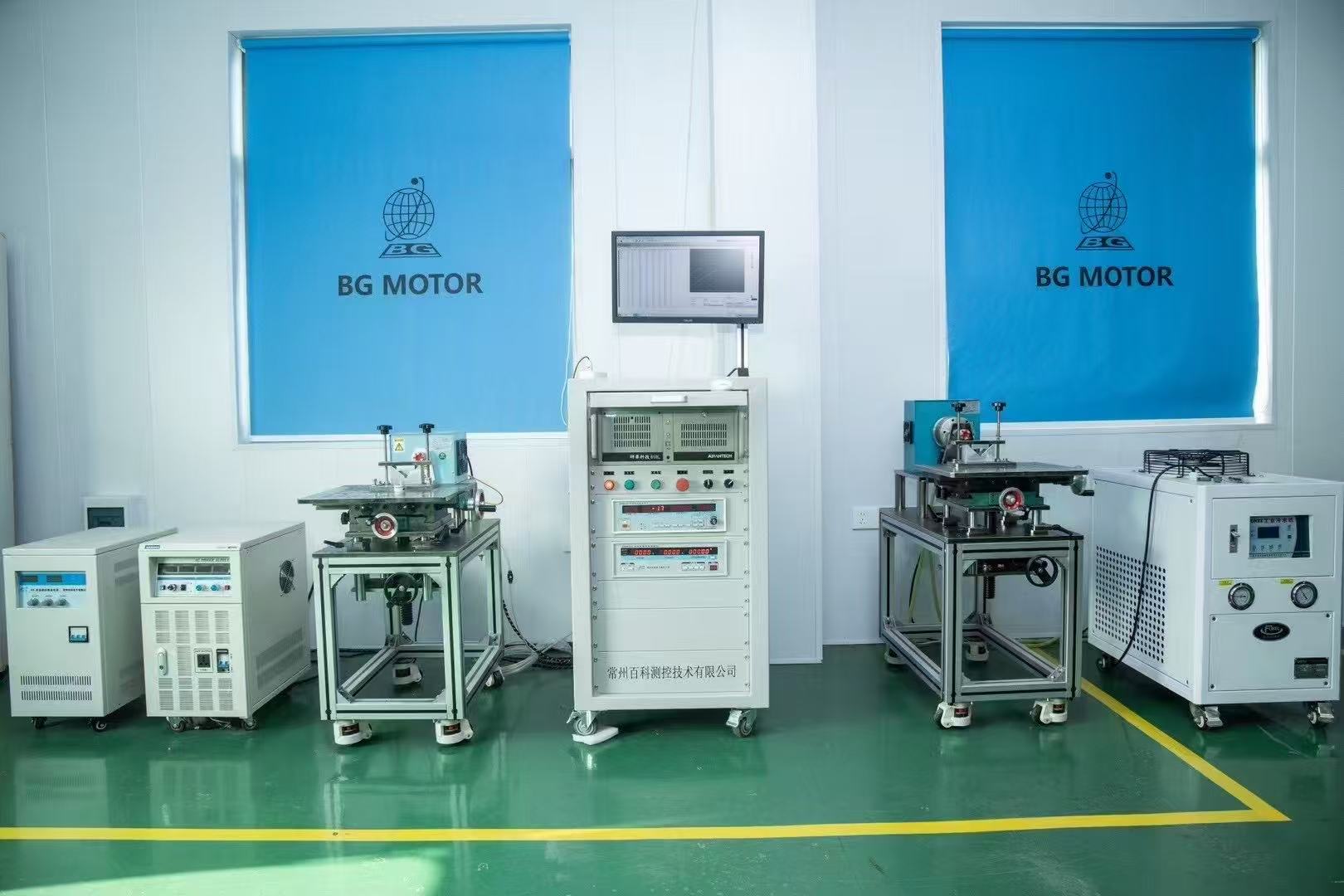

BG Motor provides a comprehensive one-stop solution for the medical motor market:

Complete Customization: From high-torque DC motors with gearboxes to compact AC motors for ventilators, we offer tailor-made motor assemblies.

Engineering Support: Our R&D team uses MotorCAD, ANSYS, and JMAG to design efficient and quiet medical-grade motors.

Integrated Solutions: We deliver motors with planetary gearboxes, encoders, electromagnetic brakes, and drivers—reducing your supplier management.

Global Quality and Certification: With CE, FCC, RoHS, and CCC certifications, our medical-grade motor solutions are trusted by OEM medical device companies in the US, Germany, Japan, and beyond.

Proven Reliability: Our factory’s 99.99% pass rate and environmental-friendly materials make BG Motor a reliable medical motor manufacturer.

By partnering with us, you get a medical motor solution that ensures high performance, long service life, and global compliance.

In short, BG Motor empowers the medical-grade motor market with customized, high-torque, low-noise solutions for modern healthcare innovation.

BACK

BACK

The EASA 2025 Annual Convention & Solutions Expo, held from July 19–22 in Nashvi…

ShangHai, July 2, 2025 – MOTOR CHINA 2025, Asia's annual motor industry even…

As global temperatures rise and summer heat waves become more frequent, fans and…

As industries worldwide move toward energy conservation and carbon neutrality, B…

BG Motor has always stayed at its post and welcomed customers from all over the …

On May 5, the 137th Canton Fair officially concluded. This "Made in China f…