Behind every intelligent action is a motor that performs the rhythm.

Hi all, it's a pleasure to share with you today an latest customer story. In this case, the main thing is to use the motor to empower the automatic bowling machine. First of all, I would like to thank the customer for their generous feedback, allowing me to obtain the right to use this video, if you are interested in sports equipment, you can transfer to this customer's website:https://hexgensports.com/home

In the era of intelligent sports, the electric motor has become the core driving force of the innovation of modern sports and fitness equipment, from the automatic treadmill to the ball throwing machine, the precision motor injects vitality into the machine, ensuring its smooth operation, real-time control, and adaptive response.

The motor used in the motion equipment in this video is BG Motor's80mm brushless DC motor, which ensures long-term use, low noise interference, and excellent continuous speed regulation. This makes the bowling machine able to continuously throw bowling balls with smooth and precise movements, reducing manual labor, improving efficiency and entertainment effects, and cleverly integrating automation and creativity.

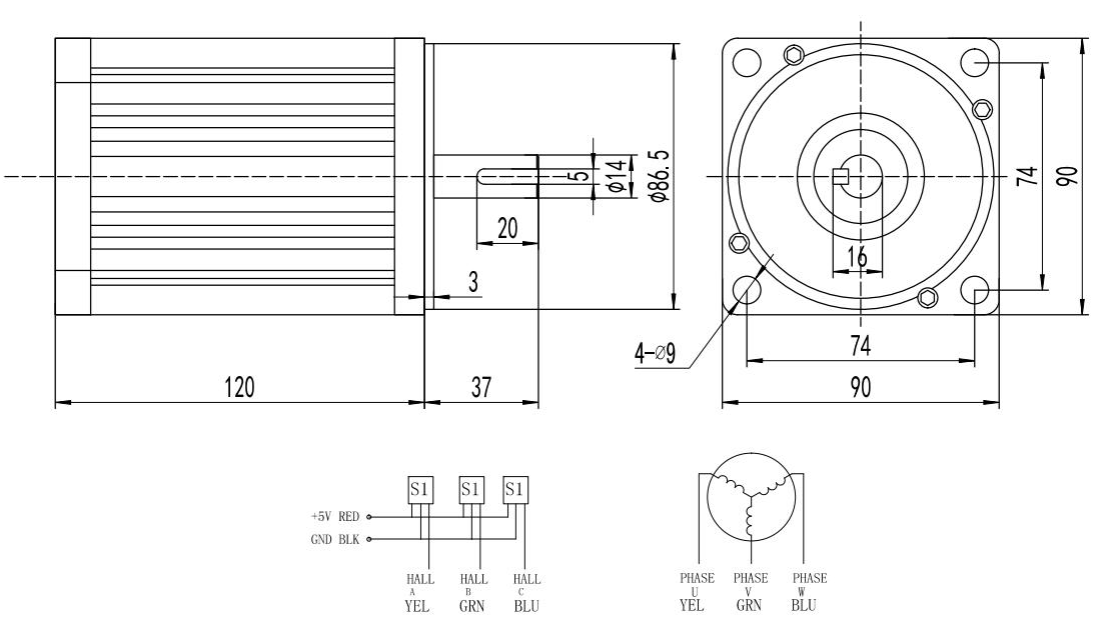

The Motor data and drawings:

| Electrical Specifications | |||||||||

| Model | RATED LOAD | NO LOAD | STALL | ||||||

| Voltage | Power | Speed | Torque | Current | Speed | Current | Torque | Current | |

| V | W | rpm | N.m | A | rpm | A | N.m | A | |

| BG80BLDC-4830S | 48 | 314 | 3000 | 1.00 | 8.2 | 4000 | 1.02 | 3.00 | 24.53 |

| BG80BLDC-4830S-1 | 48 | 565 | 3000 | 1.80 | 14.7 | 4000 | 1.84 | 5.40 | 44.14 |

| BG80BLDC-4830S-2 | 48 | 659 | 3000 | 2.10 | 17.2 | 4000 | 2.15 | 6.29 | 51.48 |

| BG80BLDC-31030S | 310 | 785 | 3000 | 2.50 | 3.2 | 4000 | 0.40 | 7.50 | 9.50 |

| We can also customize products according to customer requirements. | |||||||||

1. Rated Load

All models are rated at 3000rpm and have a moderate output for most medium-speed drivetrains.

Torque range from 1.00–2.50 N·m to meet different application scenarios from light to medium loads.

2. No Load Performance

The no-load speed is unified at 4000rpm, indicating that the motor has a strong upper speed limit.

The low no-load current (for example, only 0.4A in the 310V version) indicates that the no-load energy consumption is very low and the energy saving effect is good, which is especially suitable for continuous operation scenarios.

3. Stall performance

Stall torques range from 3.00 N·m to 7.50 N·m, and the largest model, the 31030S, can provide up to 7.5 N·m of stall torque, with good start-up and anti-blocking ability.

The corresponding locked-rotor current range is 9.50A ~ 51.48A, and it needs to be configured with matching power supply and driver.

4.Application suggestions

4830s-1 or 4830s-2, with medium and high torque, 48VDC power supply, easy to integrate, moderate load, suitable for automatic feeding equipment

The 4830s-2 has stable output, high torque, and strong load bearing capacity. It is suitable for industrial belt transmission and small lifting settings.

31030s uses 310VDC, with extremely low no-load current, good energy consumption control, suitable for continuous operation, and more suitable for high-efficiency automation equipment

Why choose the 80 series?

✔ High torque for consistent ball handling

Traditional bowling machines use a counterweight spring structure, which has the problems of unstable projection force (±15% deviation) and inability to adapt to different weight spheres (6-16 pounds), resulting in a bottle replenishment rate of up to 30%.

→Then through technology the motor can output a peak torque of 12.5N·m in 0.2 seconds, and the linear Hall sensor senses the weight of the ball in real time. When a 16-pound professional ball is detected, Turbo mode is automatically triggered to achieve 5m/s² acceleration, ensuring that the end of the 10m fairway maintains a speed of 3.2±0.1m/s.

✔ Long service life under continuous operation

Commercial bowling alleys have an average daily projection demand of 600+ times, and conventional motors need to be shut down for maintenance every 800 hours, which affects business efficiency.

→The nitriding gear set is equipped with a solid lubricating coating containing MoS₂, and the transmission efficiency remains 98.7% (industry standard is 94%) after 2000 hours of continuous operation under the condition of 120 high-frequency starts and stops per hour.

✔ Quiet, smooth performance ideal for indoor use

Indoor venues require equipment noise < 40dB, and traditional geared motors operate with noise of up to 65dB, which affects the consumer experience.

→The three-stage shock absorbing bracket (active electromagnetic damping + passive rubber vibration isolation + air spring) reduces the vibration acceleration transmitted to the fairway structure to 0.02g to avoid the resonance causing the bottle to fall over by mistake.

✔ Flexible shaft and mounting customization

There are differences in the size of the fairways in different venues (the standard fairway is 18.29m ±15%), which needs to be quickly adapted and transformed.

→The motor supports 360° rotation locking of the flange, and the ±0.1° angle fine-tuning is achieved through the laser positioning hole. With the quick-assembly fixture, the position of the whole machine can be reconstructed within 20 minutes, and it can adapt to different installation spacing of 4.5-7.2 meters.

→With parallelable design, when customers need to upgrade the dual-fairway system, the power can be synchronized by connecting two motors in parallel through the CAN bus, without changing the controller (support 1-4 motors cluster control)

✔ Reliable speed control and stability

Traditional equipment needs to manually record pitching data, which cannot achieve accurate operational analysis.

→The motor encoder records 120 parameters such as the torque curve and acceleration peak of each pitch in real time, and generates a library of the best pitching patterns through machine learning, increasing the STRIKE rate by 27%.

The program has been successfully implemented in the top 3 bowling chain brand Bowlero in the local

market, and the measured data shows that:

▼Increased equipment failure interval from 900 hours to 6,800 hours

▼19% increase in average daily revenue per lane (thanks to the quieter environment for extended peak hours)

▼83% reduction in the time required for mechanical structure adjustment (originally required to be operated by professional engineers, but now completed by the venue

personnel)

▼41% decrease in customer complaints (mainly due to reduced pitching accuracy and noise issues)

This mechatronics solution is redefining the reliability standard of entertainment and sports equipment, providing a model for the intelligent transformation of traditional entertainm-ent facilities.

Whether it's a smart rowing machine, a smart bowling system, or a fully automated training station, the path to smarter sports always starts with smarter motors.

What the hand does is what the heart dreams of.

Every motor is a hymn to creation.

100,000 rotations, just for one precise force!

BACK

BACK

Yesterday, the 138th China Import and Export Fair (Canton Fair) was grandly open…

In the golden autumn of October, the fruits are fragrant. On this beautiful mome…

Dear friends, the 138th Canton Fair will be held in Pazhou, Guangzhou on October…

At BG Motor, we firmly believe that the strength of a team can carry dreams furt…

New Breakthrough at Conifer (Silicon Valley Startup)What’s new?Conifer has devel…

The 2025 World Robot Conference (WRC), held in Beijing, brought together top min…