What’s new?

Conifer has developed a compact axial-flux electric motor that uses iron-based (ferrite) magnets instead of costly rare-earth materials—combining higher efficiency, lower cost, and reduced supply-chain risks.They offer the following unparalleled advantages:

Efficiency boost: About 20 % higher efficiency compared to conventional motors using rare-earth magnets

Rare-earth independence: By replacing neodymium with ferrite, Conifer removes reliance on geopolitically sensitive supply chains, especially those centered in China

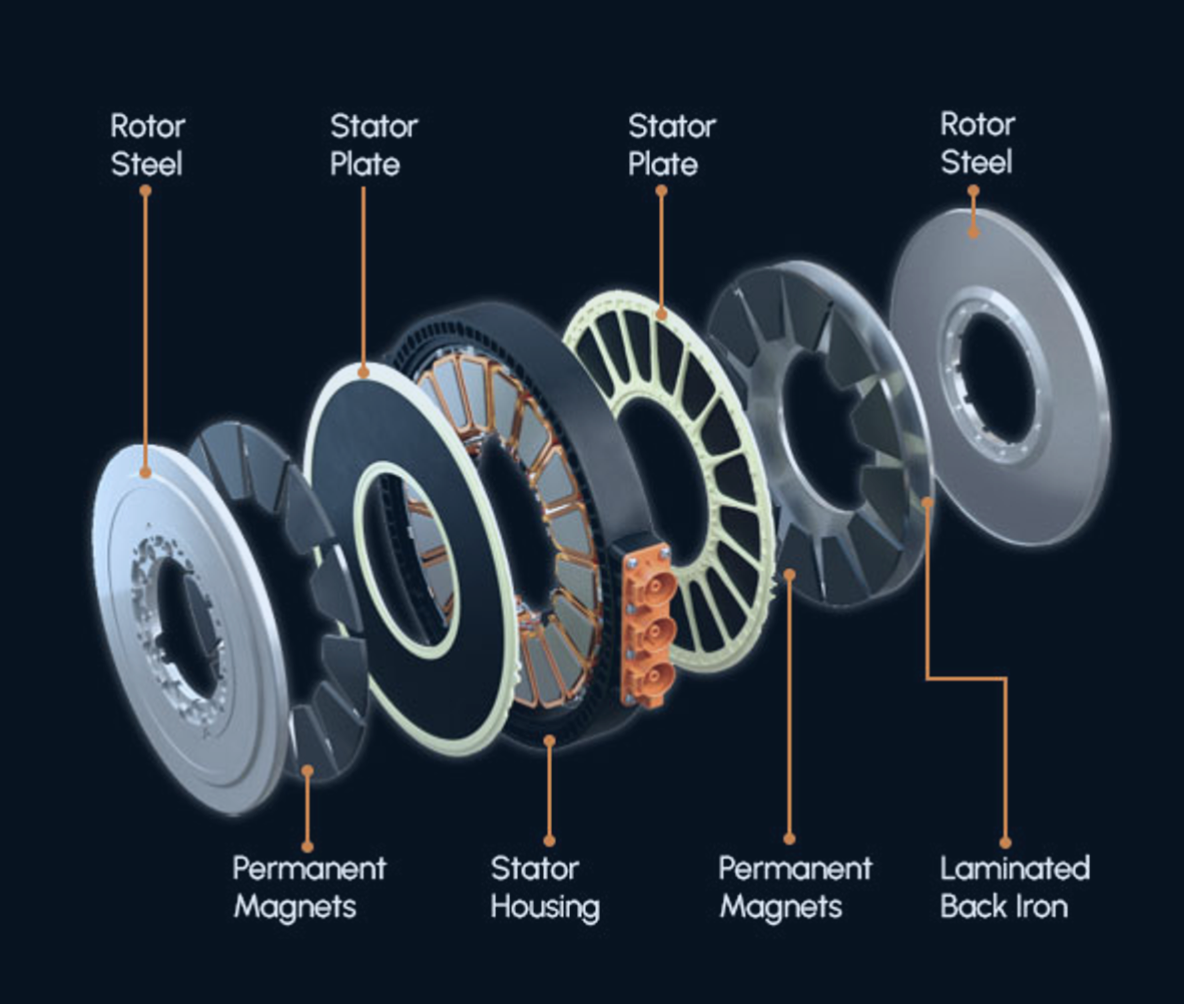

Axial-flux architecture advantage: This flat, disk-like design provides higher torque, compact size, and excellent power density—even with inherently weaker ferrite magnets .

Patented stator & manufacturing: Their proprietary stator enables a 95 % reduction in core material and nearly eliminates scrap steel

"No-Tool" process: Software-driven, modular manufacturing—one line can produce multiple motor sizes (1-25 hp) without retooling, cutting winding costs by ~90 % and simplifying production by a factor of 10

Application scope: Targeting small-mobility use cases (like scooters, lawnmowers, two-wheelers), as well as stationary uses (HVAC, pumps, tools). Motors are IE5-efficient and up to half the size and weight of standard induction motors

Funding & scale: Raised $20 million in seed funding; first units (geared in-wheel powertrains) will ship soon. Scale target: up to 75,000 units/year

Axial flux motors are used in various new technological environments with their ultra-high torque density. The most typical is the electric car, which does not require a gearbox and achieves 100% torque, which is a 4-fold difference compared to the traditional one. And the space design is more compact, smaller and lighter. And due to the flat structure, it can be produced without special casting, greatly reducing costs. In the field of aviation, new achievements have also been made

Reduce your risk: No more reliance on volatile rare-earth supply chains or spikes in material costs.

Boost performance: Higher motor efficiency translates to longer run times, lower energy use, reduced heat, and quieter operation.

Simplify sourcing: Modular, software-led production means easier ordering, faster lead times, and consistent quality.

High adaptability: Motors built for your specific use case—be it mobility or industrial—without major redesign efforts.

Edge in innovation: Align yourself with next-generation motor technology that’s poised to reshape electrification.

The progress of science and technology has once again responded to the development of the times, and under the premise that everything is chasing efficiency, we must innovate to cope with market development

BACK

BACK

Yesterday, the 138th China Import and Export Fair (Canton Fair) was grandly open…

In the golden autumn of October, the fruits are fragrant. On this beautiful mome…

Dear friends, the 138th Canton Fair will be held in Pazhou, Guangzhou on October…

At BG Motor, we firmly believe that the strength of a team can carry dreams furt…

New Breakthrough at Conifer (Silicon Valley Startup)What’s new?Conifer has devel…

The 2025 World Robot Conference (WRC), held in Beijing, brought together top min…