Brushless motors are widely used in modern automation and robotics.The advantages of brushless DC include energy saving, high efficiency, low maintenance, and low noise. The birth and R&D of brushless gear motors are mainly to solve the limitations of traditional brushless motors in low-speed and high-torque applications, and to meet the needs of more industrial automation and precision equipment

Brushless geared motors combine the efficiency of brushless motor technology with speed reducers. These motors are commonly divided into planetary geared motors and worm gear motors, which share efficiency and torque characteristics but differ in structure, direction, and application flexibility.

Just like a tree, the brushless motor is the trunk—while brushless planetary gearmotors and worm gearmotors are its major branches, each extending in different directions to meet specific application needs.

What Is Right-Angle Output vs. Coaxial Output in Speed Reducers?

What Are the Advantages and Disadvantages of Each Motor Type?

The three types differ in internal construction, output behavior, space requirements, and cost. Here's a simplified comparison table:

| Feature | Brushless Motor | Brushless Planetary Gearmotor | Brushless Worm Gearmotor |

| Internal Structure | Motor only, no gearbox | Motor + planetary gear set | Motor + worm and wheel gear set |

| Output Torque | Low | High (torque amplification through gears) | Moderate to high, with self-locking ability |

| Output Speed | High (3000–10000 rpm) | Reduced (10–500 rpm depending on ratio) | Reduced and smoother (typically <300 rpm) |

| Gear Efficiency | N/A | High (90–95%) | Lower (70–85%) due to sliding friction |

| Output Direction | Inline (coaxial) | Inline (coaxial) | Right-angle output |

| Size and Weight | Compact | Slightly bulkier due to gearbox | Bulky due to angular structure |

| Cost | Low | Moderate | Moderate to high (depending on gear ratio) |

| Applications | Fans, drones, centrifugal pumps | AGVs, robot arms, medical robots | Doors, conveyors, lifting equipment |

Coaxial output The input shaft and output shaft are arranged coaxially, such as the helical gear structure of the R series reducer, and the space utilization is optimized through a compact design. It is suitable for heavy equipment with horizontal coaxial transmission, such as cranes, conveyors, etc

Right-angle output The right-angle output adopts bevel gears (such as K series reducers) or turbine-helical gear combinations (such as S series reducers) to achieve a 90° right-angle layout between the input shaft and the output shaft. Suitable for equipment that requires vertical drive, e.g. heavy industrial machinery (K series) or light industrial equipment (S series)

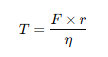

F = load force (N)

r = radius (m)

η = efficiency

Match Application Requirements

Continuous, heavy load → Brushless geared motor

Intermittent or low load → Direct brushless motor

Consider Space and Output Direction

Tight space → Worm gearmotor

Precision and inline output → Planetary gearmotor

Add a Safety Factor

For industrial use, a 20% safety margin is recommended.

Pros: High efficiency, low noise, compact size, high speed

Cons: Low torque, not suitable for direct heavy-load drive

Best For: Fans, drones, small pumps

Pros: High torque, high efficiency, inline design

Cons: Higher cost

Best For: AGVs, robotic arms, precision medical equipment

Cons: Lower efficiency, larger size

Best For: Doors, conveyors, lifting platforms

Consider the following key factors:

Torque and Speed Needs

High speed, low torque → Brushless motor

High torque, low speed → Geared motor

Installation Space and Output Direction

Inline layout → Planetary gearmotor

Tight corners or directional output → Worm gearmotor

Precision and Load Characteristics

Precise control and stable load → Planetary gearmotor

Basic drive or need for holding position → Worm gearmotor

Budget and Lifecycle Demands

Cost-sensitive → Brushless motor

High performance and durability → Geared options

As a specialized electric motor manufacturer, BG Motor supports full customization of brushless gear motors and geared brushless motors, including:

Voltage: 12V / 24V / 48V or customized

Speed: 10–5000 rpm range

Torque: Up to 100Nm with gearing

Gear Ratios: Wide range for planetary and worm setups

Output Shafts: D-cut, keyway, custom designs

Mounting Flanges: Custom flange dimensions

Certifications: CE, FCC, ROHS, ISO9001

Lifespan: ≥10,000 hours for brushless motor work

Noise Level: Optimized for low-noise medical and smart device use

IP Ratings: For dust, moisture, and industrial conditions

BACK

BACK

Yesterday, the 138th China Import and Export Fair (Canton Fair) was grandly open…

In the golden autumn of October, the fruits are fragrant. On this beautiful mome…

Dear friends, the 138th Canton Fair will be held in Pazhou, Guangzhou on October…

At BG Motor, we firmly believe that the strength of a team can carry dreams furt…

New Breakthrough at Conifer (Silicon Valley Startup)What’s new?Conifer has devel…

The 2025 World Robot Conference (WRC), held in Beijing, brought together top min…