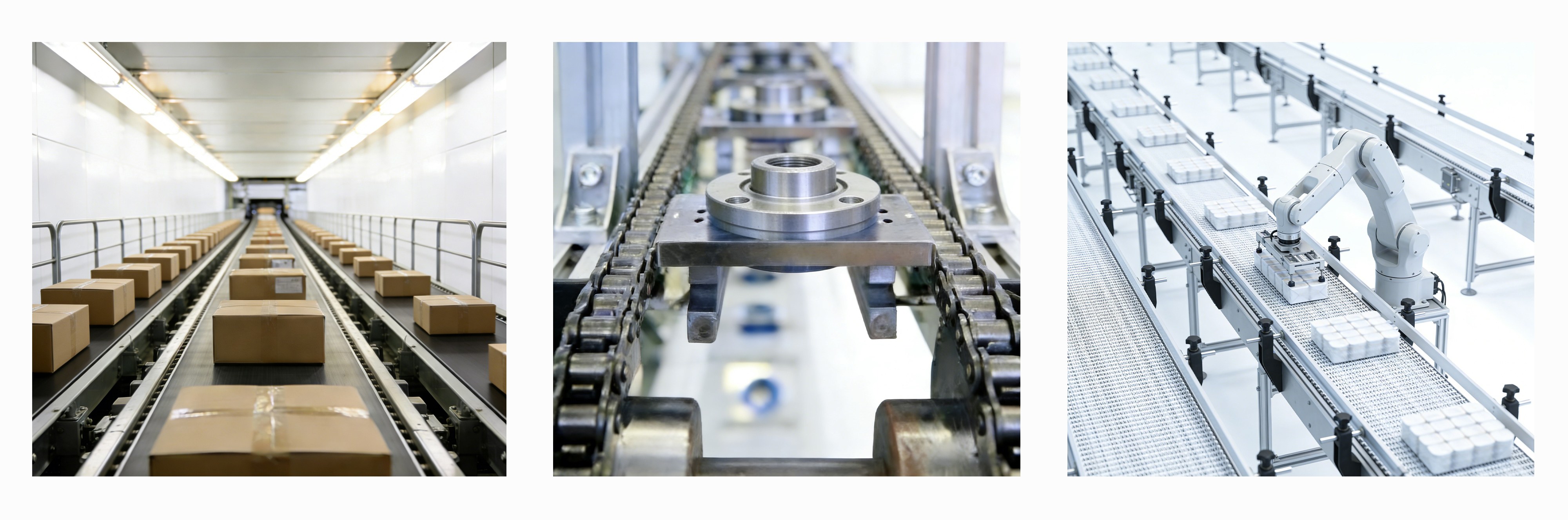

In modern industrial automation, logistics systems, food processing lines, and intelligent manufacturing, conveyor systems play a fundamental role in material handling efficiency, production continuity, and operational stability. At the core of every conveyor system is the drive motor system, which directly determines performance, reliability, energy consumption, and service life.

Different conveyor types require different motor technologies, gearbox structures, torque characteristics, control systems, and protection levels. Proper motor selection is not just power matching — it is a system engineering process.

This guide provides a structured overview of the main conveyor types and their application scenarios, technical requirements, motor matching solutions, and product keywords, optimized for industrial B2B SEO and engineering procurement.

Applications: logistics sorting lines, packaging conveyors, food processing conveyors, electronics assembly lines, light industrial automation

Technical Data:

Load capacity: 10–2000 kg

Speed range: 0.1–2.5 m/s

Duty cycle: S1 continuous duty

Control system: VFD control / DC speed control

Matching Motor Solutions:

DC Gear Motor

AC Gear Motor

BLDC Gear Motor

Drum Motor (Motorized Pulley)

Applications: warehouse logistics, pallet conveying systems, distribution centers, intelligent sorting systems

Technical Data:

Load per roller: 50–300 kg

Speed: 0.2–1.5 m/s

Control: zone control / segmented drive

Matching Motor Solutions:

Motorized Roller

24V / 48V BLDC Roller Motor

AC Motor + Gearbox

Applications: automotive production lines, heavy equipment manufacturing, steel plants, industrial assembly lines

Technical Data:

Heavy-load conveying (ton-level)

Speed: 5–60 rpm

Working conditions: dust, oil, high impact

Matching Motor Solutions:

AC Gear Motor

Worm Gear Motor

Planetary Gear Motor

Applications: food drying lines, washing lines, sterilization systems, baking ovens

Technical Data:

Temperature range: -20°C to 300°C

Environment: high humidity, high temperature, corrosive atmosphere

Matching Motor Solutions:

Stainless Steel Gear Motor

IP65 / IP67 Waterproof Motor

AC Gear Motor

Applications: powder conveying, cement industry, grain handling, chemical material transport

Technical Data:

High starting torque

Continuous operation

Anti-blocking requirement

Matching Motor Solutions:

Worm Gear Motor

Planetary Gear Motor

AC Induction Motor + Gearbox

Applications: mining transport systems, inclined logistics conveyors, grain lifting systems

Technical Data:

High torque demand

Heavy-load startup

Anti-backdrive requirement

Matching Motor Solutions:

High Torque DC Gear Motor

Worm Gear Motor (self-locking)

Planetary Gear Motor

Motor selection for conveyor systems follows a system engineering model:

Load + Conveyor Structure + Operating Conditions + Control System + Protection Level + Service Life

Final configuration:

Conveyor System + Drive Motor + Gearbox + Control System + Protection Class

Conveyor systems are not simple mechanical structures — they are core infrastructure of intelligent manufacturing systems. Motors are not just power sources — they are core components for system stability, efficiency, and reliability.

Professional motor matching delivers:

Higher system reliability

Lower energy consumption

Longer service life

Lower maintenance cost

Better control precision

Correct motor selection = lower total system cost + higher operational efficiency + long-term stability.

BACK

BACK

With the continuous upgrading of global manufacturing, the rapid growth of new e…

As 2025 comes to a close, we would like to take this moment to sincerely thank a…

Merry Christmas from BG MotorAs Christmas approaches, we would like to take this…

On Thanksgiving Day at the end of November, all BG Motor members went to Jinggan…

On behalf of our BG Motor team, we would like to express our sincerest gratitude…

Yesterday, the 138th China Import and Export Fair (Canton Fair) was grandly open…