Customer Name: Mark Wilson

Customer Industry: Automation equipment

Cooperation time: 2025

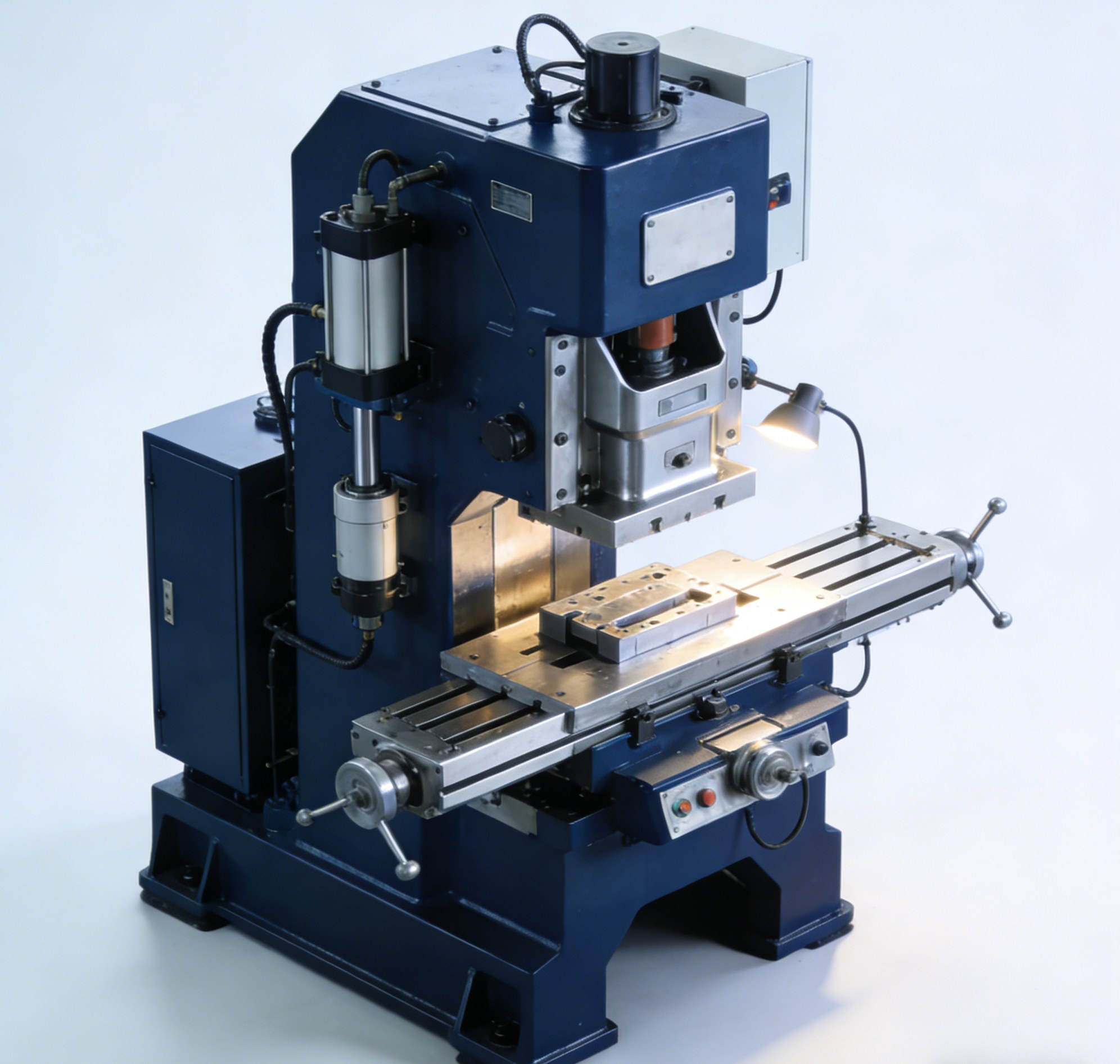

Stamping machines and forming equipment are core machines in metal forming, automotive parts manufacturing, appliance production, and industrial component processing.

These machines typically operate under:

Extremely high load

Frequent impact and shock

Low-speed, high-torque output

Strict requirements on transmission rigidity and reliability

Conventional gear motors or single-stage reducers often suffer from insufficient torque, backlash, poor impact resistance, and short service life in such applications.

The equipment manufacturer required a drive system capable of:

Very high output torque for heavy forming and stamping

Strong rigidity to withstand repeated impact loads

Stable low-speed operation

High load capacity and long service life

Compact structure for easy integration

Reliable performance under continuous industrial operation

According to the customer's application scenario and data requirements, we recommended the newly BG126ZYT Double RV geared motorThe specific details are as follows:

Model: BG126ZYT

Motor type: DC brushed motor

Rated power: 500W

Reduction type: Double RV reducer

Max output torque: 260 N·m

Voltage range:24V/48V/110V/180VDC

Drive mode: Electric motor +Double RV reduction

Application focus: High-load industrial machinery

Up to 260 N·m output torque

Ideal for stamping and forming actions

Stable torque even under sudden load changes

Dual RV stages for higher reduction ratio

Excellent load distribution

Significantly improved transmission rigidity

Designed for frequent stamping impact

Reduces stress on mechanical components

Improves overall machine durability

Suitable for forming equipment requiring stable positioning

Maintains accuracy under repeated cycles

After installation and long-term operation:

The drive system delivered stable and powerful torque output

No performance degradation under continuous heavy load

Excellent resistance to impact during stamping cycles

Reduced mechanical vibration and wear

Improved equipment stability and production efficiency

The customer confirmed that the BG126ZYT double RV reduction motor fully meets the demanding requirements of industrial stamping and forming machines.

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.