Client: Aric

Industry: Industrial robots

Cooperation time: July 2023

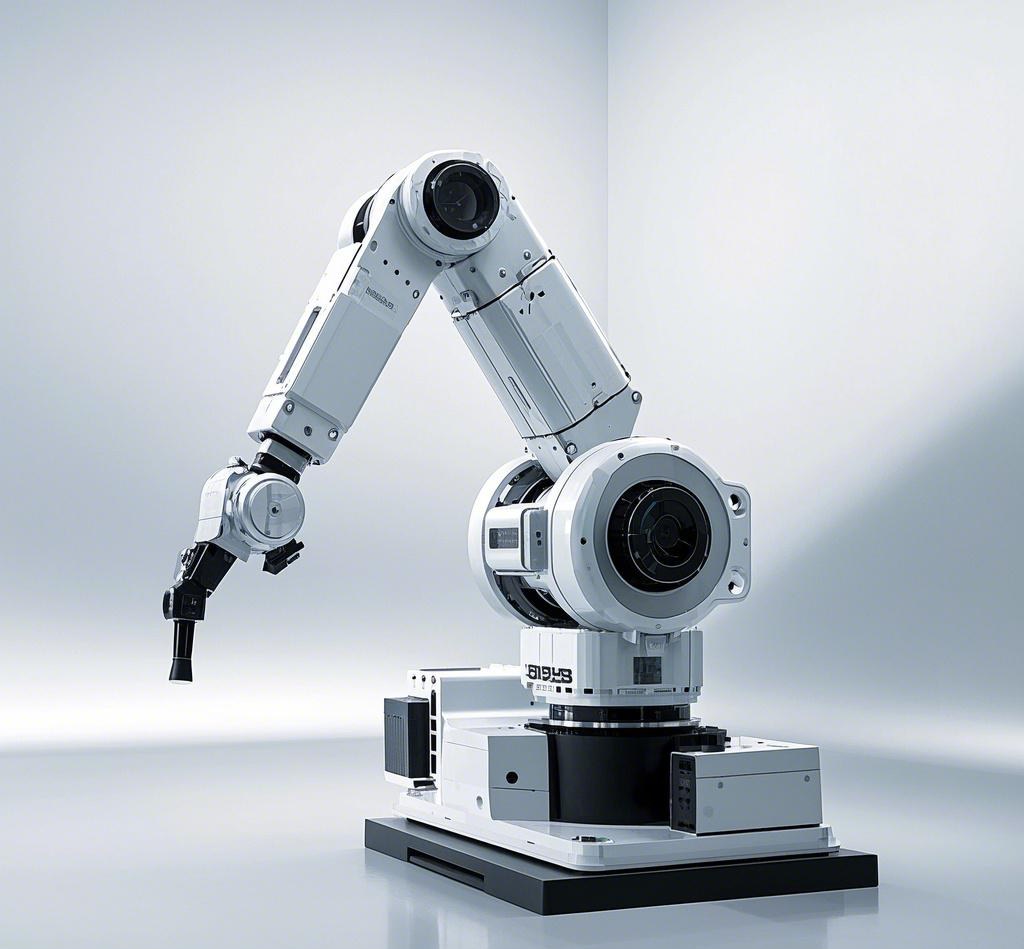

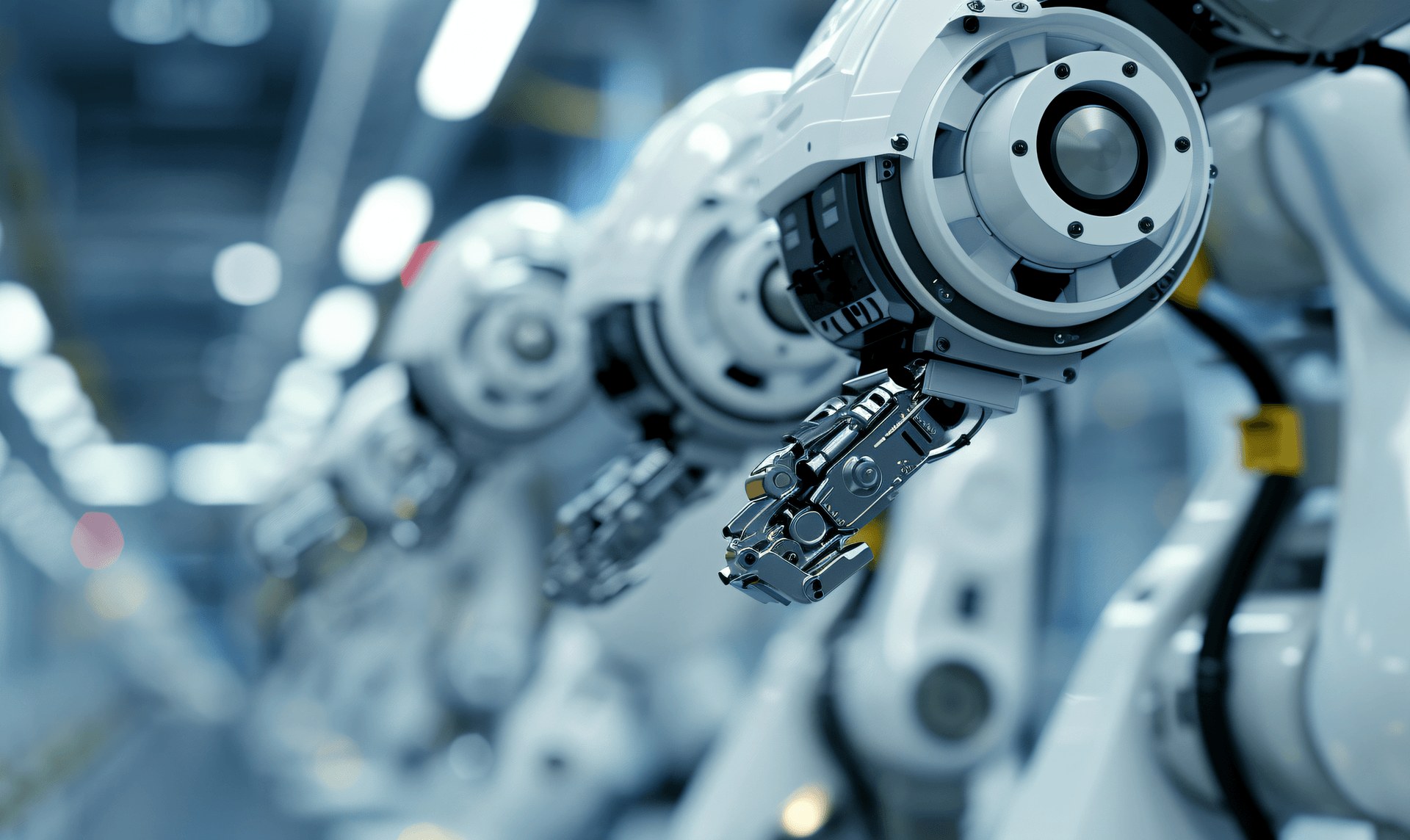

A leading intelligent robotics company specializing in the development of industrial robotic arms and AGV (Automated Guided Vehicle) robots approached BG Motor to supply a motor solution for their next-generation heavy-duty robotic arm. The robotic arm was designed for high-precision operations in automated manufacturing lines, handling tasks such as material lifting, precise assembly, and load transfer in confined spaces.

The client’s goal was to enhance the robot’s performance with motors that offer high torque, long service life, lightweight design, and robust environmental protection for harsh industrial environments.

1、High Torque Demand:

The robotic arm needed to handle heavy payloads up to 150 kg with high precision, requiring robot arm motors with strong torque output while maintaining smooth operation.

2、Long Service Life:

The client required dc motor for robot arm capable of operating 24/7 with minimal maintenance in high-duty cycles, ensuring a service life of over 20,000 hours.

3、Environmental Protection:

The robot arm motors had to withstand harsh conditions, including dust, moisture, and oil exposure, common in industrial environments. A high IP rating was mandatory.

4、Weight Constraints:

To optimize the robot’s efficiency and speed, the high precision motor needed to be lightweight, reducing the overall load without compromising torque output.

After analyzing the client’s requirements, BG Motor provided a customized DC Gear Reduction Motor solution featuring:

Output Torque:Up to 250 Nm, achieved through an optimized planetary gear system.

Stable Performance:The robot arm motor delivers consistent torque even at low speeds, ensuring precise control during lifting and rotation tasks.

Durability:High quality bearings,low friction materials,and advanced thermal management reduce wear and extend motor life beyond 20,000 hours.

Continuous Duty:Designed for 24/7 operation in industrial environments without performance degradation.

Sealed Housing:The high precision motor for automation robot arm is rated IP65, providing excellent resistance to dust, water, and oil.

Corrosion-Resistant Materials:Ideal for use in harsh industrial environments where exposure to chemicals and moisture is common.

Compact Structure:Use of lightweight alloy materials reduces the robot arm motor’s weight by 15% compared to conventional models.

Efficiency:The lighter weight reduces energy consumption and enhances the robot’s movement speed and flexibility.

Welcome to the related product pages

BG Motor is committed to providing comprehensive after-sales support, ensuring the client’s long-term satisfaction:

Technical Support:100% technical assistance for troubleshooting and performance optimization.

Maintenance Training:On-site or remote training sessions for the client’s engineering team to handle routine inspections and maintenance.

Spare Parts Supply:Rapid delivery of spare parts to minimize downtime in case of unexpected failures.

Performance Monitoring:Optional remote monitoring systems to track motor health and predict potential failures before they occur.

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.