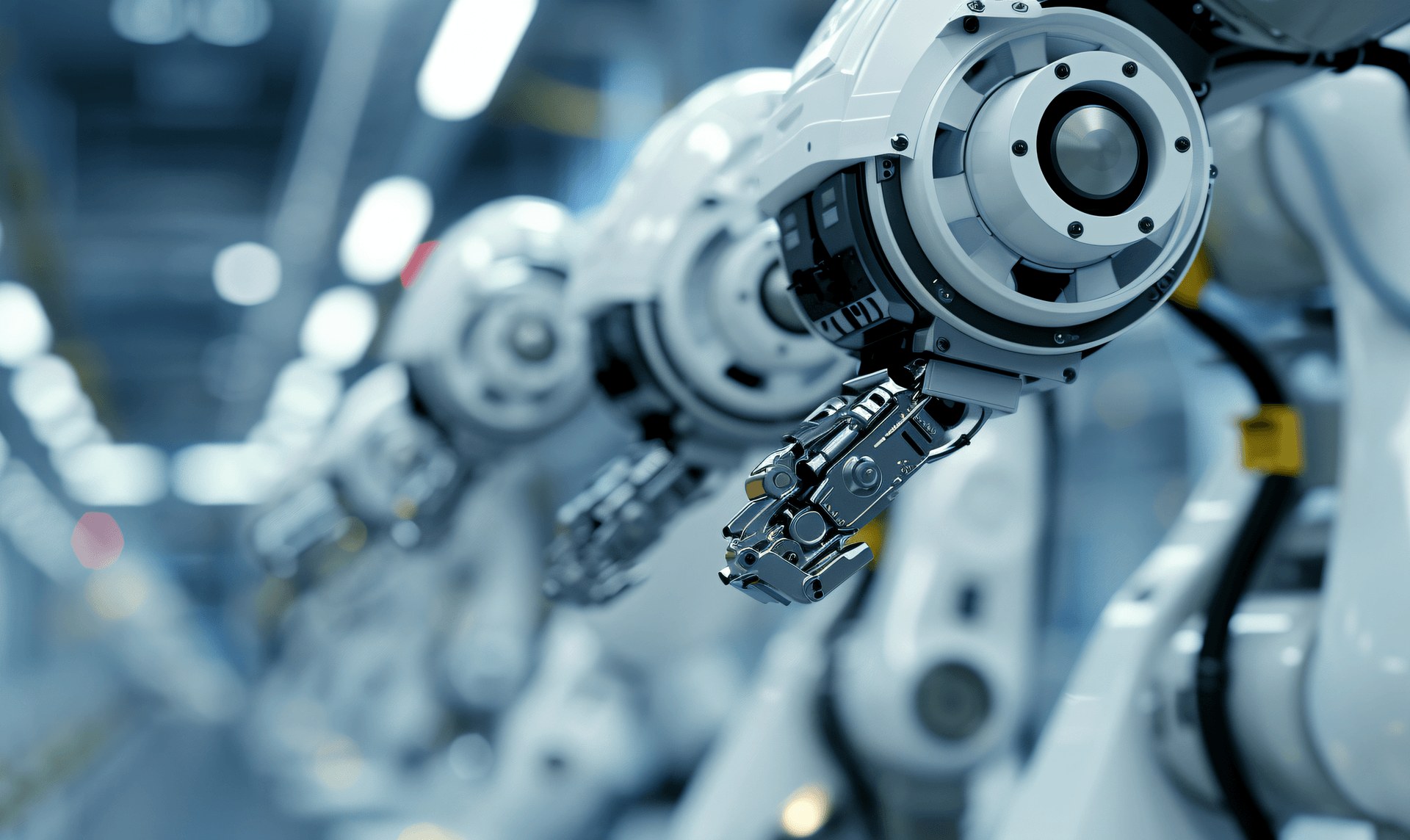

An internationally renowned electronics manufacturing company needs to complete multiple processes in a very short cycle time on a new generation of automated production lines, including component picking, precise positioning, assembly and inspection. The production line uses a multi-station high-speed turntable with an end-grabbing system that requires the best balance between high speed and high precision.

Due to the company's long-term 24-hour operation of the production line, which places extremely high requirements on the stability, longevity and energy consumption of the equipment, and the compact space layout, any drive system must be miniaturized and highly integrated.

The beat is demanding

The start and stop of the dial and gripper must be done in milliseconds to meet the beat requirements of hundreds of cycles per minute. The traditional motor has a large inertia and slow acceleration and deceleration, resulting in production cycle bottlenecks.

Equipment space is limited

The installation space of the turntable drive and gripping mechanism is limited, and large drives cannot be arranged. The motor needs to have a high power density to output sufficient torque and speed within a limited size.

Torque stability and gripping safety

Grippers need to hold a variety of components of different materials and shapes, which must be both stable and avoid damage to the workpiece. When production cycles are fast, instantaneous torque fluctuations can cause product to drift or fall.

High precision positioning requirements

The turntable transposition and the clamp closure position must maintain an accuracy of ±0.05~0.1mm, otherwise it will affect the assembly yield. After long-term operation, ordinary drives are prone to accumulated errors and mechanical loosening.

It adopts BG Motor high-speed low-inertia brushless DC motor, with a speed of up to 100,000 RPM, with extremely low inertia, achieving millisecond-level start-stop, significantly improving response speed.

The durable DC motor diameter can be at least 28mm, and the compact structure can be directly embedded into the shaft center of the turntable or the end of the clip to reduce the transmission link and improve space utilization.

It is paired with a high-precision planetary reducer to provide smooth and high output torque, ensuring clamping stability and smooth operation of the turntable.

Integrate high-resolution encoder and smart driver to achieve closed-loop control of speed and position; support multi-stage speed curve and torque limiting functions.

IP65~IP68 protection level, adapted to dust and humid environments; brushless structure is maintenance-free, and the lifespan can reach tens of thousands of hours.

Welcome to browse our DC motor products

Increased production efficiency: Single-cycle cycle cycle time is shortened by 18%, and the production capacity of the entire line is increased by about 20%.

Space Savings: The drive system takes up 25% less space, leaving more leeway for equipment upgrades and maintenance.

Improved accuracy: The positioning error is controlled at ±0.05mm, and the assembly yield rate is significantly improved.

Stable operation: 6 months of continuous operation without abnormal downtime, noise control of ≤40dB.

Reduced Energy Consumption: The motor operates efficiently, reducing the energy consumption of the entire line by approximately 12%.

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.