A system integrator specializing in automated industrial equipment was developing a compact lifting platform used in an automation line for height adjustment and positioning between different workstations.

The lifting function was not designed as a high-speed main lift, but rather as a controlled vertical adjustment module, requiring stable movement, safe holding position, and simple control integration.

The customer was looking for a cost-effective and reliable geared motor solution that could ensure the platform would remain in position when power is off, without adding complex braking systems.

During the design phase, several technical challenges were identified:

Safety requirement: no back-driving

The lifting platform must not drop or slide down when power is cut off.

Low-speed, high-torque output needed

The lifting motion required slow and smooth movement, not high speed.

Limited installation space

The motor had to be compact and easy to integrate with a lead screw mechanism.

Simple control system preferred

The customer wanted to avoid additional electromagnetic brakes or complex servo systems.

Stable performance for intermittent operation

The platform would adjust height multiple times per shift, but not continuously.

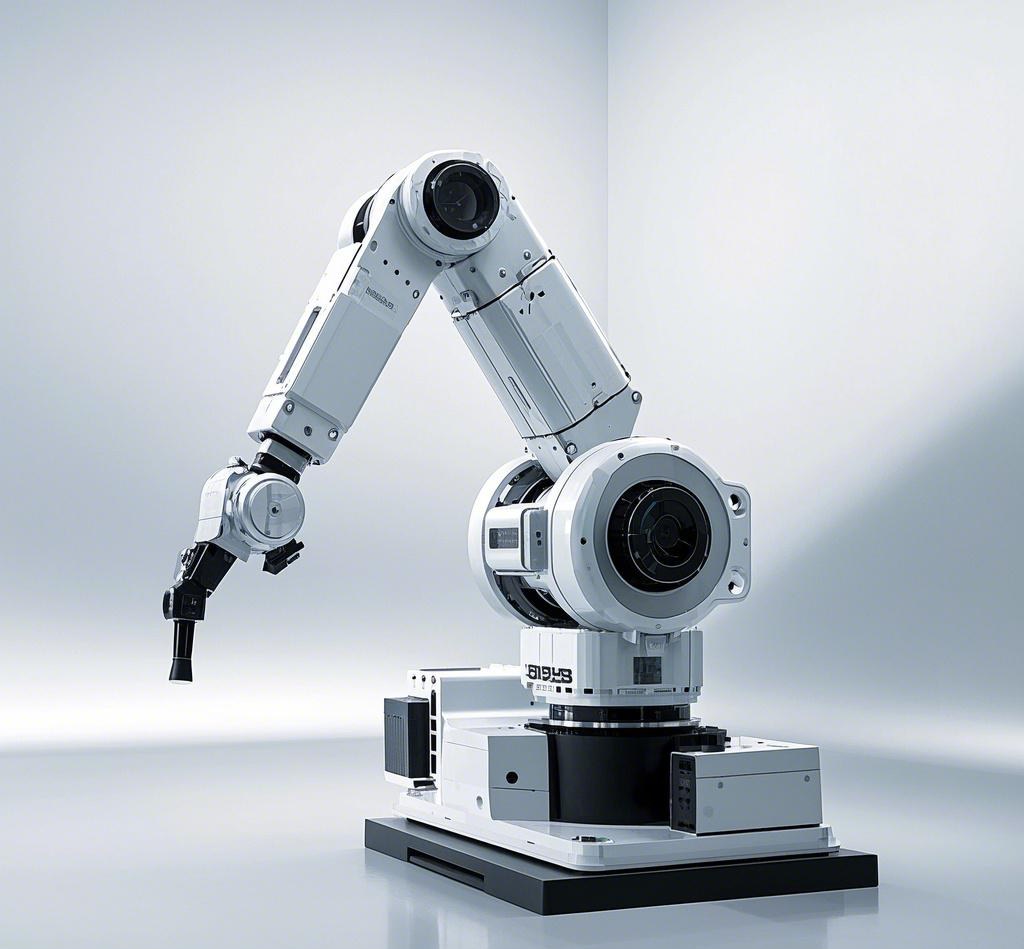

After evaluating the application requirements, BG Motor recommended the worm gear geared motor from the 613 series, configured to work with a lead screw lifting mechanism.

Motor Type: Worm Gear Geared Motor

Output Speed: 3–30 RPM

Output Torque: High torque suitable for lifting adjustment

Voltage Options: DC / AC available (depending on configuration)

Key Feature: Self-locking worm gear structure

Self-locking function

The worm gear structure prevents back-driving, ensuring the lifting platform stays in position when power is off.

Smooth low-speed output

Ideal for controlled vertical movement and precise height adjustment.

Compact and integrated design

Easy to mount directly to the lead screw or lifting mechanism.

No additional brake required

Reduces system complexity, cost, and maintenance requirements.

After installation and testing, the customer reported:

Stable and smooth lifting movement

No platform sliding when power is off

Reduced system complexity due to elimination of braking components

Reliable performance during repeated adjustment cycles

The solution met all functional and safety requirements of the automated lifting system.

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.