With the gradual development of sports training in the direction of intelligence and automation, automatic ball throwing machines are more and more widely used in table tennis, baseball, tennis and other training projects. Traditional manual pitching is not only laborious and inefficient, but also difficult to maintain a consistent training intensity. In order to improve the quality of training and reduce labor costs, the customer wanted to develop an intelligent automatic ball bowling machine with high efficiency, low noise and stable projection ability.

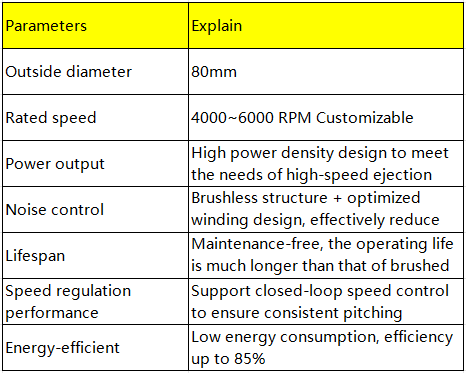

In order to meet the working needs of high-frequency and continuous operation of the equipment, the customer finally chose the 80mm brushless motor produced by BG Motor as the core power unit.

In the early stages of project development, the customer faced the following technical challenges:

1. High speed drive requirements: The ball throwing machine needs to throw the ball at a stable speed, and the motor speed is required to be between 3000~6000 RPM, and it needs to be kept running for a long time without attenuation.

2. Poor speed stability: Some traditional motors fluctuate significantly under high loads, which affects the consistency of pitching trajectory.

3. Excessive noise: Indoor training has high requirements for silence, and traditional brushed motors are noisy.

4. Frequent equipment maintenance: Some motors have a short service life, and the maintenance of carbon brushes is cumbersome, which increases the after-sales burden.

5. Compact structure requirements: the overall volume of the equipment is limited, and there are strict restrictions on the size and weight of the motor.

Efficient training:The motor rotates at high speed to drive the catapult wheel, simulating the real pitching action, and the training is closer to the actual combat.

Intelligent adjustment:With the electronic control system, the pitching speed, frequency and direction can be adjusted.

Manpower saving:No need for manual assistance, to achieve one-key start, automatic ball supply, fully automatic operation.

Silent operation:Suitable for scenarios with high noise requirements such as homes, schools, and indoor training centers.

Size optimization:The compact structure of the motor reserves more space for wiring and heat dissipation for the device.

1. Technical Support

Provide 3D drawings, electrical schematic diagrams, and controller matching schemes.

It can assist in the commissioning of the whole machine to ensure the efficient docking of the motor and the control system.

2. Customized service

The motor length, speed and voltage parameters can be adjusted according to customer needs.

Custom bearings, shaft outlets, and mounting holes are available.

3. Warranty Service

All motors come with an 18-month warranty.

In case of non-human quality problems, BG Motor provides free replacement service.

4. Responsiveness

Provide 7×12 hour online technical response service.

Samples can be shipped quickly and verified with overseas testing.

BACK

BACK

BG Motor insisting on producing the best quality motors for our customers.