When many engineers think of a “custom motor,” they often imagine only small adjustments—like changing the voltage rating or extending the shaft length. But a true motor manufacturer like BG Motor can go much further. By working on the mechanical structure, electromagnetic performance, control integration, and environmental protection, we create motors that are perfectly adapted to your equipment instead of forcing your design to adapt to the motor.

Here are 7 powerful customization options you may not know you can request:

Standard shafts rarely match every machine interface.A mismatch creates the need for adapters, which introduce tolerance errors, vibration, and even premature bearing failure.

At BG Motor, shafts can be customized in diameter, length, step design, keyways, or threads according to your drawings.

AGV wheels benefit from D-cut shafts that lock securely, ensuring no slippage during acceleration.

Medical centrifuges require ultra-precise, ground shafts with minimal runout to guarantee balance at high speeds.

This level of customization ensures reliable torque transmission and longer service life for your system.

We can design flanges, mounting holes, and housing geometries to match your machine’s structure. This makes motor installation seamless, reduces assembly space, and eliminates the need for redesigns.

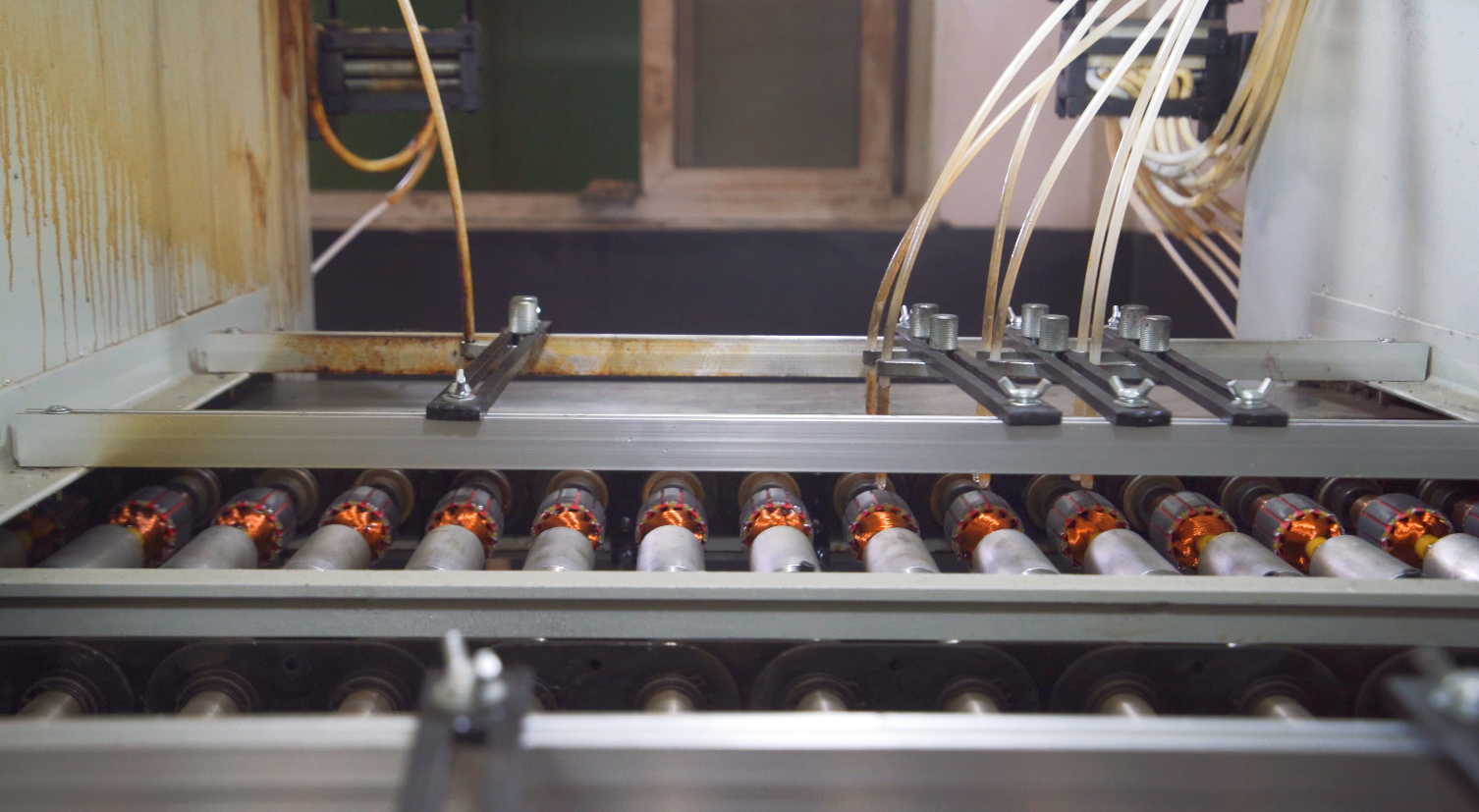

Not every application runs the same way. Some require high starting torque, others need steady low-speed performance. Off-the-shelf motors often fail to meet these unique load profiles.

With electromagnetic design expertise and simulation tools like ANSYS, JMAG, and MotorCAD, BG Motor engineers can tailor the torque–speed curve of your motor.

Robot arms need smooth, low-speed torque for precise positioning—something we achieve with optimized winding and planetary gear integration.

Industrial lifting systems require motors with high peak torque and thermal protection for repetitive heavy-duty cycles.

Instead of compromising your design, BG delivers a motor that fits your duty cycle perfectly.

Dust, water, and harsh environments can quickly damage motors. With customized IP65, IP67, or IP68 sealing, your motor can handle outdoor, medical, or cleaning equipment applications without performance loss.

By using different insulation classes (B, F, H) and advanced thermal-resistant materials, we can ensure stable operation in high-temperature environments. Optimized heat dissipation paths prevent overheating, increasing durability.

We can integrate encoders, drivers, or electromagnetic brakes directly into the motor housing. This gives you a complete mechatronic system, saving integration time and guaranteeing compatibility. Ideal for AGVs, robotics, and automated production lines.

For applications where comfort and precision matter—such as medical devices, smart home equipment, or office machinery—we optimize bearing selection, rotor balance, and housing stiffness. The result: low-noise, low-vibration motors that run smoothly and quietly.

Customization is not just a service at BG—it’s our engineering philosophy. With:

30+ years of R&D experience

Advanced design tools (ANSYS, JMAG, MotorCAD)

Full in-house production with strict quality control

Global certifications (CE, ROHS, CCC)

We provide brushless DC motors, planetary geared motors, AC motors, robot motors, and integrated drive systems that meet your exact requirements.

Whether you’re building AGVs, robotic arms, medical centrifuges, conveyors, or smart devices, BG Motor delivers motors that are high-precision, long-life, low-noise, and perfectly matched to your system.

Next time you request a “custom motor,” don’t stop at voltage or shaft length. Ask for a motor that is engineered for your application’s torque, speed, structure, and environment.

With BG Motor, you don’t just buy a motor—you gain a tailor-made drive solution that makes your equipment smarter, stronger, and more reliable.

We are proud to endorse our products that have always been professionally developed, we are even more happy that every customer receives the most satisfactory electric motor, we look forward to any feedback from you, we will be responsible for our products to the end

BACK

BACK

Yesterday, the 138th China Import and Export Fair (Canton Fair) was grandly open…

In the golden autumn of October, the fruits are fragrant. On this beautiful mome…

Dear friends, the 138th Canton Fair will be held in Pazhou, Guangzhou on October…

At BG Motor, we firmly believe that the strength of a team can carry dreams furt…

New Breakthrough at Conifer (Silicon Valley Startup)What’s new?Conifer has devel…

The 2025 World Robot Conference (WRC), held in Beijing, brought together top min…