Corrugated gaskets (also known as wave washers or corrugated washers) are circular thin sheet fasteners with a regular wavy shape, mainly used to prevent loosening of mechanical connections and cushion shocks. It has multiple important roles in mechanical connection.

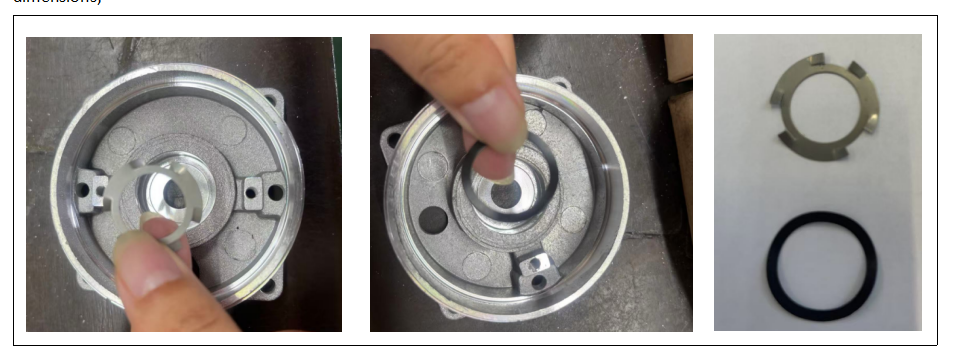

Corrugated gaskets are usually installed on the bearing side of the front end of the motor (non-driving end) to compensate for axial displacement and maintain bearing preload. This position can effectively suppress the axial movement of the rotor caused by thermal expansion or vibration, and avoid friction between the stator and the rotor. Some double-ended bearing motors may also need to install a waveform gasket at the drive end, but this needs to be confirmed according to the specific design

When the corrugated gasket is installed, it needs to cooperate with the bearing to ensure that the elastic deformation is evenly distributed and avoid local stress concentration. and preload control, comprehensively considering factors such as rotor gravity and vibration impact.

1. Axial displacement compensation

Absorbs thermal expansion and vibration

During the operation of the motor, due to temperature changes or electromagnetic force, the shaft will produce axial displacement, and the waveform gasket compensates for this displacement through elastic deformation (such as three-wave peak structure) to avoid friction between the rotor and the stator core.

Measured data shows that the axial travel momentum of the motor without waveform gasket can reach more than 0.5mm, resulting in a 50% acceleration of bearing wear.

Maintain bearing preload

The corrugated gasket provides stable axial preload through compression deformation, preventing excessive bearing clearance and ensuring rotor positioning accuracy.

2. Vibration and noise control

Damping and vibration reduction

The elastic properties of the waveform gasket can absorb high-frequency vibration energy and reduce the motor operating noise (10-15 dB reduction).

In automobile motors, it can effectively suppress engine compartment resonance.

Prevent mechanical loosening

Under dynamic loads (e.g. start/brake), the corrugated gasket prevents the bolt or bearing cover from loosening through friction and avoids secondary vibrations caused by loosening

3. Protection and prolongation of life

Reduce bearing and shoulder wear

Axial movement will cause wear of the bearing running ring or shoulder, and the corrugated gasket distributes the load through preload to extend the bearing life.

Insulation and sealing assistance

Suppressing axial displacement can avoid internal wiring pulling and reduce the risk of winding insulation damage. At the same time, reduce the seal failure caused by vibration in the bearing chamber.

1. Classification according to use

Ordinary corrugated gasket

It is suitable for general mechanical connections, used to prevent loosening, cushioning and protect the surface of the connector

Bearing special corrugated gasket

Specially designed for bearings, it is used to compensate for axial displacement and maintain bearing preload, and is commonly used in motors, precision instruments, and other scenarios

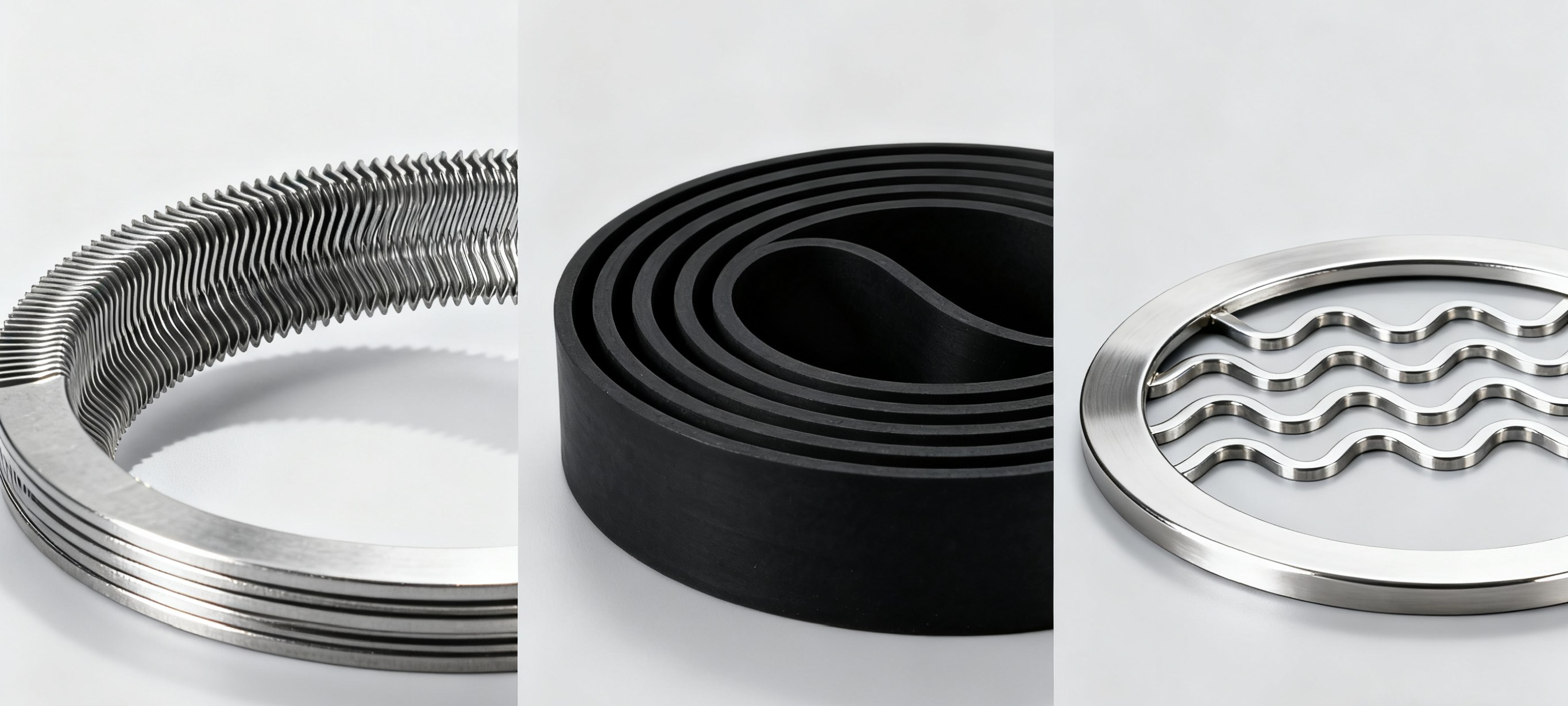

2. Classification by material

Carbon spring steel (such as 65Mn).

High elasticity, suitable for high-load environments, such as heavy machinery, automobile chassis, etc

Stainless steel (such as 304/316L).

It has strong corrosion resistance and is suitable for humid or corrosive environments such as chemical industry and food machinery

Rubber corrugated gasket

For sealing and vibration damping, it must comply with GB/T 528-2009 standard, suitable for low-pressure sealing scenarios

3. Classification according to structure

Single wave gasket

Single-layer wave structure, suitable for light preload compensation (such as electronic equipment, small motors).

Three-wave gasket

Multi-layer wave structure, more elastic, used in high vibration or shock environments (such as aerospace, heavy machinery).

Multi-layer corrugated gasket

Layered metal sheets for higher elastic compensation for extreme conditions (e.g. pressure vessels)

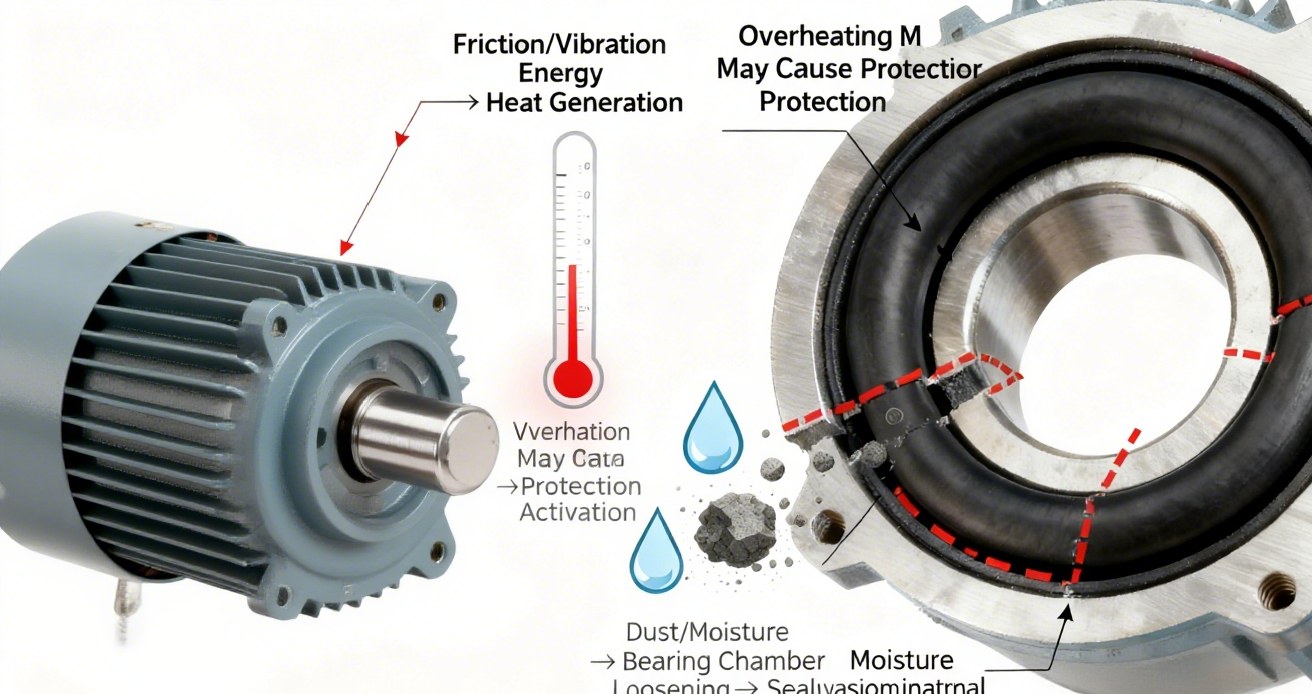

1. Core impact

Axial movement intensifies

The corrugated gasket absorbs the axial displacement caused by thermal expansion or vibration of the motor shaft through elastic deformation, and without the gasket, the mating gap between the shaft and the bearing cannot be compensated, resulting in the misalignment of the rotor and stator core, causing mechanical friction and electromagnetic imbalance .

Long-term travel can accelerate bearing wear and even lead to shaft fracture (low-stress rotational bending fatigue fracture).

Vibration and noise increase significantly

The bearing clearance increases due to the preload of the non-wave gasket, and the stability of the rotor decreases when the motor is running, resulting in high-frequency vibration and abnormal noise

Vibration can be transmitted to the load equipment through the coupling or base, affecting the overall system reliability

Bearing life is shortened

The corrugated gasket controls the axial load of the bearing through preload, and the bearing is prone to premature failure due to shock loads (such as starting, braking) after its absence

2. Typical fault performance

Abnormal increase in current: Axial turbulence leads to uneven air gap of the stator rotor, increased fluctuation of electromagnetic force, and increase of motor current

Excessive temperature rise: increased friction and vibration energy loss are converted into heat, which may trigger overheating protection.

Seal failure: The bearing chamber is loose due to vibration, and dust or moisture invades the inside of the motor

Some manufacturers omit waveform gaskets in low-power motors and replace them with flat gaskets, but they cannot provide compensatory performance, which is more common in cost-sensitive manufacturing, and reliability will decrease significantly in the long run. Internationally renowned brands such as ABB and Siemens usually strictly follow IEC standards and are equipped with corrugated gaskets as standard, but some low-priced competitors may reduce costs by simplifying the design, so under this condition, BG Motor always promises that any motor produced will match the standard corrugated gasket, so you don't have to worry about your cost rising, and we will bear all the costs.

BG Motor is professional and trustworthy enough for the products we produce, and we are responsible enough for our customers, and every consultation is the possibility of both parties to explore and grow.

BACK

BACK

Yesterday, the 138th China Import and Export Fair (Canton Fair) was grandly open…

In the golden autumn of October, the fruits are fragrant. On this beautiful mome…

Dear friends, the 138th Canton Fair will be held in Pazhou, Guangzhou on October…

At BG Motor, we firmly believe that the strength of a team can carry dreams furt…

New Breakthrough at Conifer (Silicon Valley Startup)What’s new?Conifer has devel…

The 2025 World Robot Conference (WRC), held in Beijing, brought together top min…