This is the primary cause of electromagnetic brake failure, usually related to power supply and control.

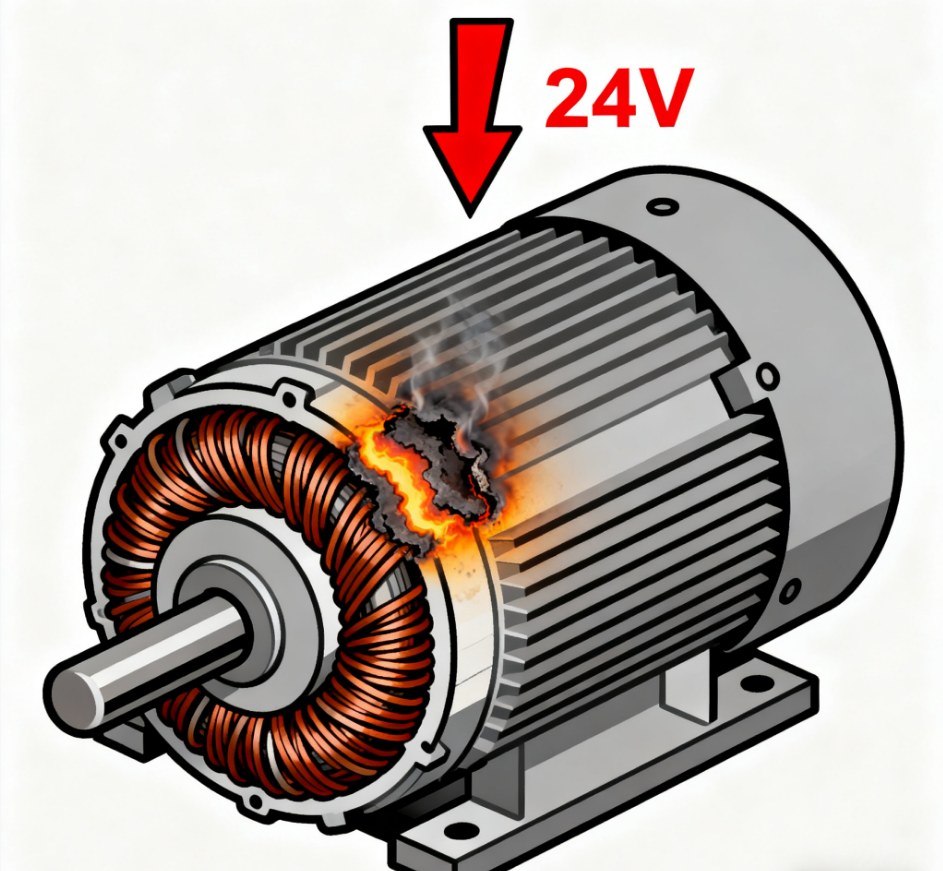

Over voltage: If the voltage supplied to the brake coil is continuously or momentarily much higher than 24V (for example, power fluctuation, wrong connection), the coil will overheat, insulation layer burned out, and eventually cause short circuit or open circuit of the coil.

Voltage deficiency: When the voltage remains below rated levels (e.g., 20V), it causes insufficient electromagnetic force from the brake coil to fully engage the brake pads. This creates a "semi-engaged" state between the brake pads and braking surface, resulting in excessive friction and high temperatures. Simultaneously, the coil overheats due to excessive current flow. These combined effects lead to rapid damage from dual mechanical stress.

Voltage surge and spike pulse: The start and stop of the power grid or surrounding high-power equipment (such as contactors, frequency converters) will produce instantaneous high voltage pulses that break down the insulation of the coil.

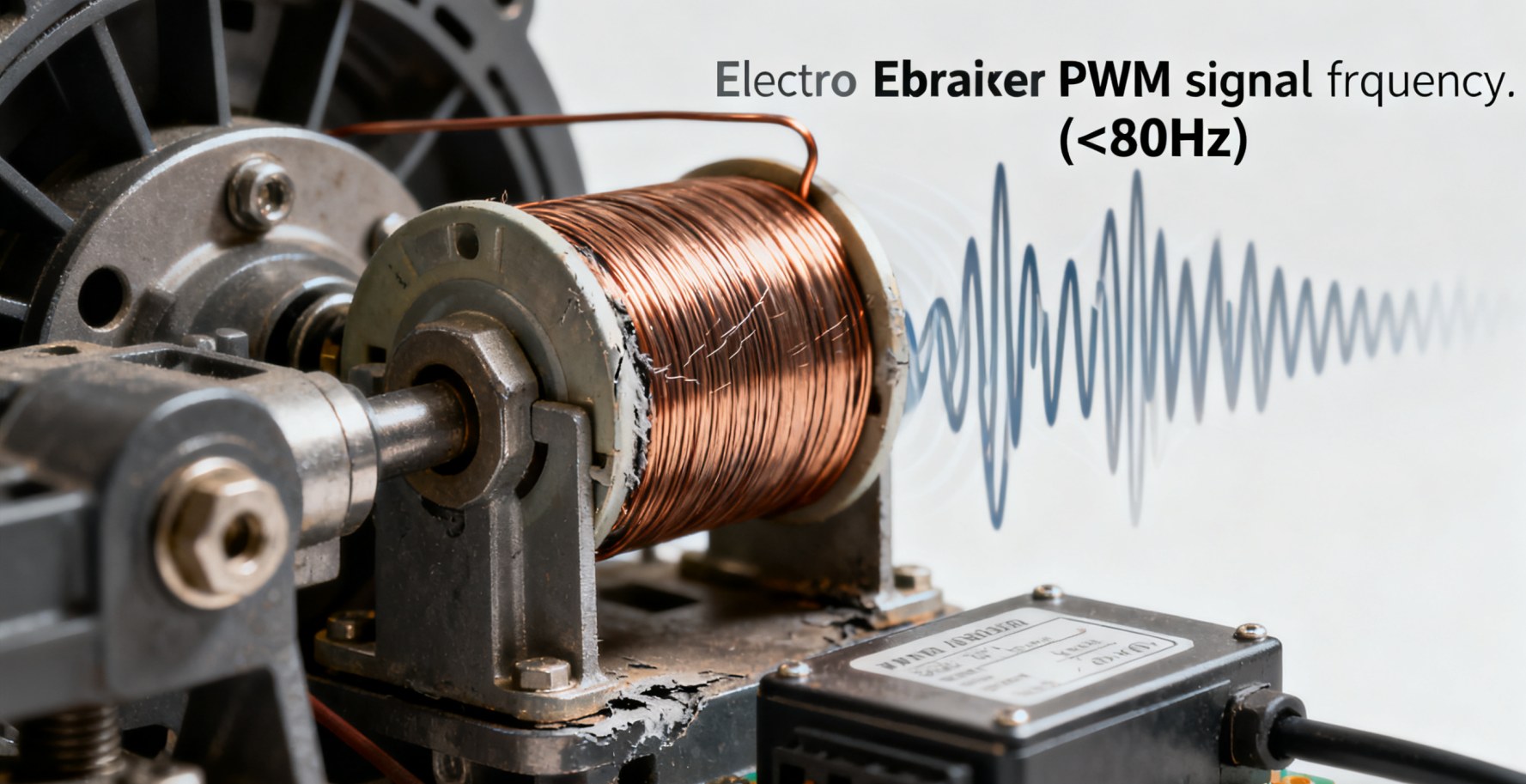

Improper PWM (Pulse Width Modulation) control: When using PWM signals to control brakes for soft-starting or speed regulation, insufficient PWM frequency can cause frequent coil energization and de-energization cycles. This results in intense vibrations and noise, accelerating wear on both mechanical components and the coils. The recommended frequency should generally be above 80Hz.

Rectifier Diode Failure: Most electromagnetic brakes incorporate a rectifier diode in parallel, either internally or externally, to absorb the reverse electromotive force (EMF) generated by the coil during power loss. If this diode becomes damaged or improperly connected, the high EMF can directly damage the control relay or transistor, and may even destroy the coil itself.

Contact failure: loose, oxidized and false connection of terminal will lead to increased resistance, local overheating, or cause power on and off, resulting in electric arc and voltage shock.

Too thin or too long wire: If the wire is too thin or too long, the voltage drop on the line will be too large, and the actual voltage reaching the brake coil will be insufficient, which is equivalent to operating under voltage.

This part is mainly related to the physical wear and brake components fatigue.

Wear of brake pads: Brake pads are consumables, and after long use, they will wear to the limit, resulting in excessive brake clearance, which can not be effectively released even if the coil is energized, or insufficient braking force. This is the most common form of "performance damage".

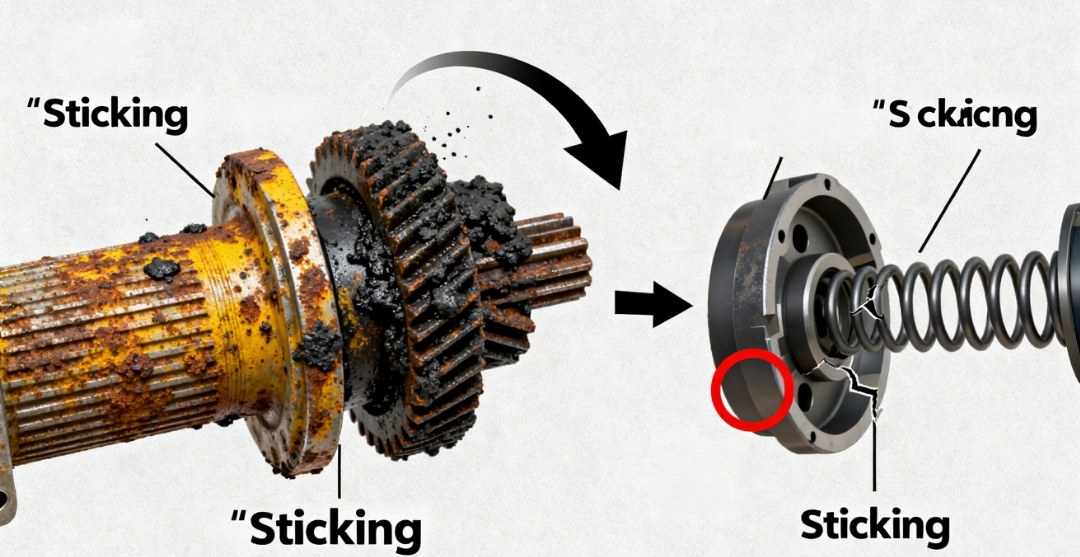

Rust and pollution: In a humid, dusty and corrosive gas environment, the brake moving parts (such as the armature and spline bushing) are prone to rust or be stuck by oil sludge and dust, resulting in their failure to move normally, brake release or engagement.

Component fatigue or fracture: the elasticity of the reset spring is weakened after long-term use, resulting in reduced braking force; or the moving parts such as the armature crack or even break due to long-term impact.

Improper brake clearance: The air gap is not adjusted correctly according to the instructions during installation. If the gap is too small, the brake pad may not be completely separated, resulting in dragging and heating; if the gap is too large, the electromagnetic force is insufficient to attract and release.

Different center or deviation: The connection between the motor and the load is different center, resulting in the brake disc running deviation, resulting in additional vibration and wear.

BACK

BACK

Yesterday, the 138th China Import and Export Fair (Canton Fair) was grandly open…

In the golden autumn of October, the fruits are fragrant. On this beautiful mome…

Dear friends, the 138th Canton Fair will be held in Pazhou, Guangzhou on October…

At BG Motor, we firmly believe that the strength of a team can carry dreams furt…

New Breakthrough at Conifer (Silicon Valley Startup)What’s new?Conifer has devel…

The 2025 World Robot Conference (WRC), held in Beijing, brought together top min…