In many industrial applications, the failure of a gear motor is not caused by poor quality, but by incorrect selection and matching. If the motor does not truly match your equipment’s load, speed, and duty cycle, problems such as noise, overheating, short life, or insufficient torque will appear quickly.

This article explains how to correctly select and match a gear motor, using practical engineering logic that you can directly apply to your project.

Gear motor selection must always start from your equipment, not from a motor catalog.

You should clearly define:

Required output torque (N.m)

Include starting torque, peak load, and possible shock load.

Required output speed (RPM)

This is the working speed under load, not no-load speed.

Load characteristics

Constant load, variable load, impact load, or frequent start-stop.

Duty cycle

Continuous operation (S1) or intermittent operation (S2 / S3).

Key point:

Most selection errors happen because only rated power is considered, while starting torque and real load are ignored.

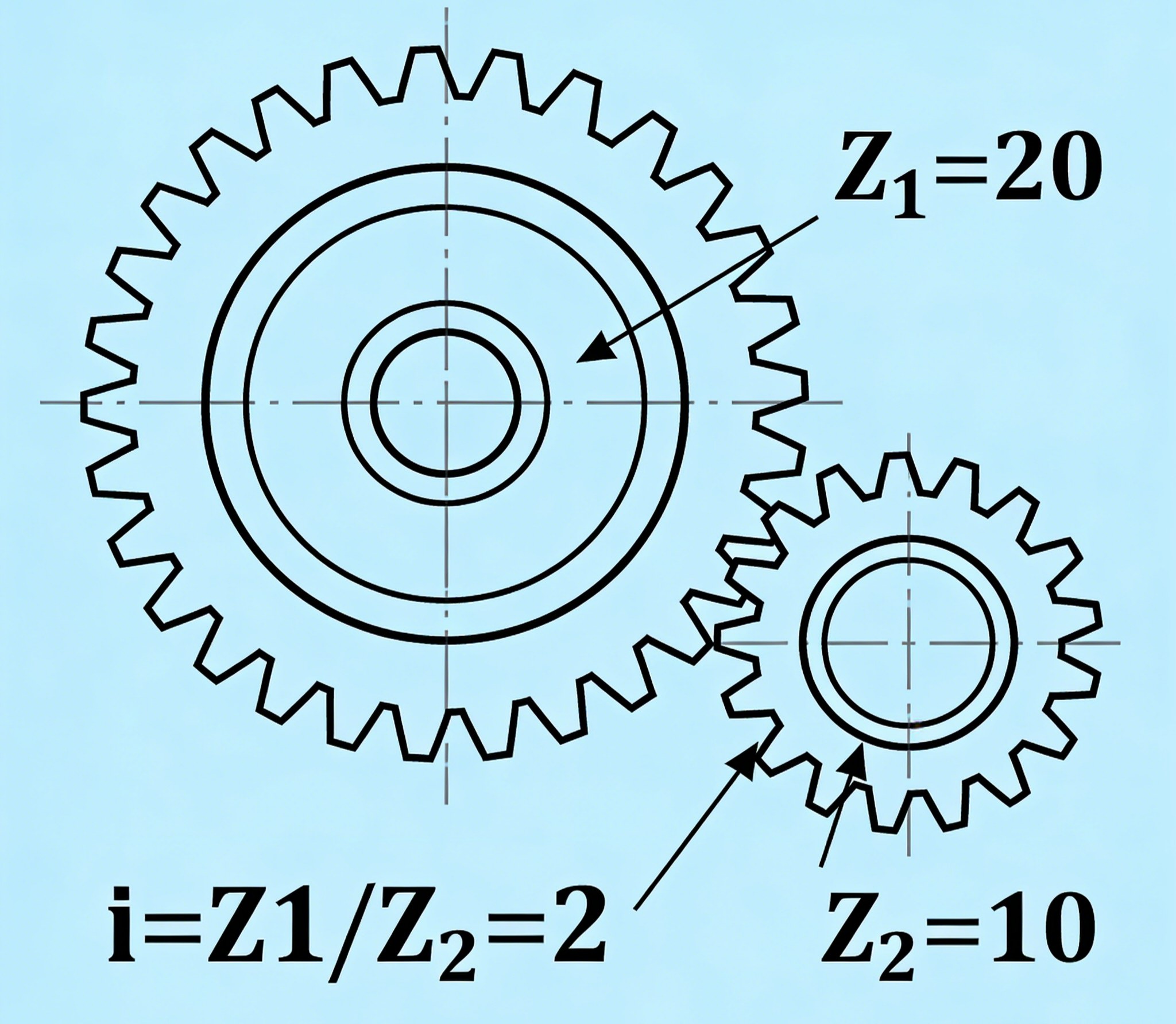

The gear ratio determines whether the motor can reach the required speed and torque efficiently.

Basic formula:Gear Ratio=Input SpeedOutput Speed

AGV, mobile robots, drive wheels: 10–50

Robot joints, lifting systems: 30–100

Automatic doors, conveyors: 20–60

A higher gear ratio increases torque but may reduce efficiency and increase noise. The ratio must be balanced, not maximized.

Different motor types suit different performance and cost requirements.

Brushless DC gear motor

Low noise and vibration

High efficiency

Ideal for AGV, robots, medical and automation equipment

The product sizes shown in the figure are 57mm, 86mm, 130mm, and 126mm BLDC Geared Motors,they are ultra-high performance and are suitable for 24V/48V/220V/310DC equal voltage mode,35W-3000W,0.4-300N.m.The gearbox has high efficiency and is suitable for industrial, medical and other precision fields.

Brushed DC gear motor

Simple control

Lower cost

Suitable for cost-sensitive industrial equipment

The above shows the best-selling models of BG: 52mm, 63mm, and 110mm DC brushed geared motors, as long as they are suitable for 12-220VDC, 40W-600W application equipment.If you have other data matches and needs, we have a wider range of motor options

Worm gear motor

High reduction ratio

Self-locking function

Suitable for lifting, positioning, and safety-related applications

The worm gear worm motor has a wide data range, suitable for 3W-3000W, 12V/48V/110V/310VDC&110V-230VAC, 0.5-300N.m.The lead wire, shaft, protection level, etc. can be customized according to the needs, suitable for most precision instruments on the market

At BG Motor, we combine DC brushed motors, BLDC motors, and planetary or worm gearboxes to match different application needs.

To ensure long service life, the gear motor must never run at its limit for long periods.

Recommended rules:

Actual working torque ≤ 70–80% of rated output torque

Starting torque and stall torque must not exceed gearbox limits

Verify gearbox load capacity and bearing life

Running continuously at maximum torque is one of the main causes of early gear motor failure.

For modern equipment, especially robots and medical devices, mechanical performance is critical.

You should evaluate:

Gear precision and backlash

Noise level and vibration

Gear material and heat treatment

Alignment between motor shaft and gearbox

High-precision planetary gear motors provide low backlash, low noise, and stable output, which is why they are widely used in high-end equipment.

Even a well-selected gear motor will fail if installation is incorrect.

Check carefully:

Motor diameter and length limits

Output shaft type (D-shaft, round shaft, spline, hollow shaft)

Mounting hole position and tolerance

Axial and radial load on the output shaft

BG Motor supports custom shafts, mounting patterns, and housing designs to match your equipment perfectly.

Standard gear motors are suitable for general applications, but many projects require customization.

Customization options include:

Gear ratio

Output shaft structure

Gear material and accuracy

Motor winding, voltage, speed, and torque curve

Encoder, brake, or driver integration

A customized gear motor reduces system risk, improves performance, and shortens development time.

Correct gear motor selection and matching is a system-level engineering task, not a simple model choice.

If you provide:

Application scenario

Required speed and torque

Duty cycle and load type

Installation constraints

BG Motor can help you complete gear motor selection, calculation, and verification, ensuring stable performance, long life, and low noise in real operation.

Choosing the right gear motor once is far better than replacing the wrong one many times.

BACK

BACK

With the continuous upgrading of global manufacturing, the rapid growth of new e…

As 2025 comes to a close, we would like to take this moment to sincerely thank a…

Merry Christmas from BG MotorAs Christmas approaches, we would like to take this…

On Thanksgiving Day at the end of November, all BG Motor members went to Jinggan…

On behalf of our BG Motor team, we would like to express our sincerest gratitude…

Yesterday, the 138th China Import and Export Fair (Canton Fair) was grandly open…