Traditional logistics can't keep up with the speed and precision modern supply chains demand. High labor costs, inefficiency, and error-prone systems are hindering competitiveness. Under the times,intelligent logistics powered by automated motor technology is reshaping the future of warehousing and delivery.

The deep integration of intelligent logistics and automated electric motor manufacturing has transformed every link in the logistics chain—from warehousing to final delivery—with unmatched efficiency, speed, and accuracy.

Electric motors serve as the core driving force behind the logistics revolution, enabling precise, efficient, and automated movement across all stages.

Traditional logistics relied heavily on manual labor, leading to high costs, slower operations, and increased human error. Tasks such as inventory counting, material handling, and order fulfillment were time-consuming and inconsistent. Downtime and miscommunication between stages further delayed delivery timelines.

In contrast, modern intelligent logistics leverages smart sensors, AGV motors, and conveyor motors to automate repetitive processes. The result is a dramatic improvement in speed (operations up to 3× faster), cost savings (labor and error-related loss reduced by over 40%), and accuracy (error rates dropping below 0.5%). Intelligent logistics systems can run 24/7, analyze real-time data, and make adjustments without human intervention, ensuring superior reliability and performance.

Modern intelligent logistics workflows are data-driven and modular, typically consisting of the following key stages:

1. Automated Warehousing: Smart systems receive goods, identify them via RFID or QR codes, and assign optimal storage locations. DC brushless motors power automated lift systems and robotic arms for precise movement.

2. Handling and Sorting: Conveyor motors and sorting robots handle material transfer across zones. AGV motors enable guided vehicles to transport goods safely and efficiently between areas.

3. Distribution and Last-Mile Delivery: Drone motors support airborne delivery where terrain limits land access. Vehicles integrated with intelligent electric motors complete local delivery routes autonomously.

Each stage is interconnected, forming a seamless logistics chain driven by responsive, efficient electric motors tailored to each task.

Electric motors are foundational in many intelligent logistics applications:

AGV Trolleys: These autonomous guided vehicles use high-torque brushless electric motors to navigate warehouses, reducing manual handling.

Conveyor Belts: Conveyor motors ensure continuous, stable product flow across various processing and sorting stations.

Drones: Drone motors enable fast, flexible, and terrain-independent delivery, especially in last-mile logistics.

Logistics Sorting Robots: Equipped with precise servo or DC motors, these robots can identify, pick, and place items accurately based on system commands.

Each of these systems demands motors that are compact, energy-efficient, and capable of high-load operation—qualities that BG Motor specializes in.

BG Motor has over 30+years of motor manufacturing experience, with a dedicated engineering team comprising power, structure, and mechanical specialists. Our R&D focuses on designing high-performance motors tailored to intelligent logistics applications.

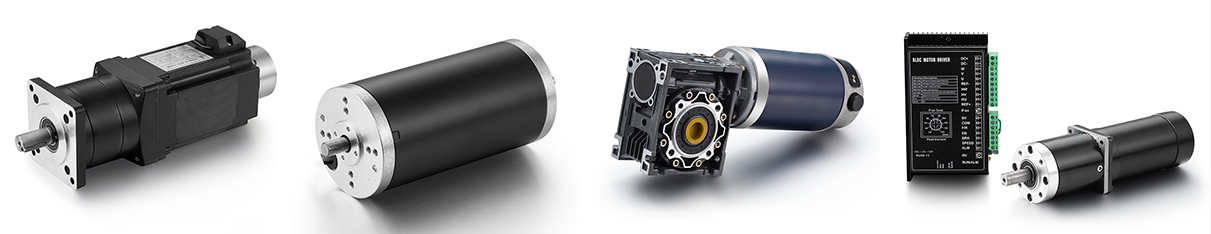

We use advanced simulation software (ANSYS, MotorCAD, JMAG) to optimize motor design for AGV, conveyor, and drone applications. Our brushless planetary geared motors, worm gear motors, and high-speed motors are engineered to deliver maximum torque and reliability in compact spaces—perfect for automated logistics systems.

These above motors have the characteristics of low noise, large torque and long life, which are the best choice to match the application of logistics and transportation industry, and can be matched with brakes, encoders and other motor parts, all of which are DC power supply, such as 12VDC, 24VDC, 48VDC, 110VDC, etc., if you have special needs, we can also providecustomized voltage, protection level, etc.

All our motors can be customized for voltage, shaft size, mounting type, and protection grade (up to IP68), ensuring seamless integration into your equipment.

A leading European AGV manufacturer needed a reliable motor solution that could operate 16 hours daily under high load with minimal maintenance. BG Motor provided a custom brushless planetary geared motor with built-in encoder and brake, ensuring precise movement and quick stops.

The results were remarkable: system uptime increased by 35%, energy consumption dropped by 20%, and customer maintenance calls fell dramatically. This partnership showcases our ability to deliver tailored, high-performance solutions for demanding logistics applications.

BG Motor offers end-to-end support tailored to intelligent logistics motor needs:(You can watch our production video via our link)

- Customized Motor Design: We adapt size, voltage, speed, and torque to match your system.

- Integrated Systems: From motor drives and brakes to encoders and gearboxes—all in one solution.

- Quality Assurance: Our products maintain a pass rate of 99.99%, with CE, CCC, ROHS,ISO9001 certifications.

- Technical Reports: Every motor is delivered with test data and performance curves.

- Global Logistics Support: Exporting to the US, Germany, Japan, and more, we understand international compliance and logistics needs.

No matter your role—engineer, product designer, or procurement manager—our team works closely with you to deliver optimized motor solutions.

BACK

BACK

Yesterday, the 138th China Import and Export Fair (Canton Fair) was grandly open…

In the golden autumn of October, the fruits are fragrant. On this beautiful mome…

Dear friends, the 138th Canton Fair will be held in Pazhou, Guangzhou on October…

At BG Motor, we firmly believe that the strength of a team can carry dreams furt…

New Breakthrough at Conifer (Silicon Valley Startup)What’s new?Conifer has devel…

The 2025 World Robot Conference (WRC), held in Beijing, brought together top min…